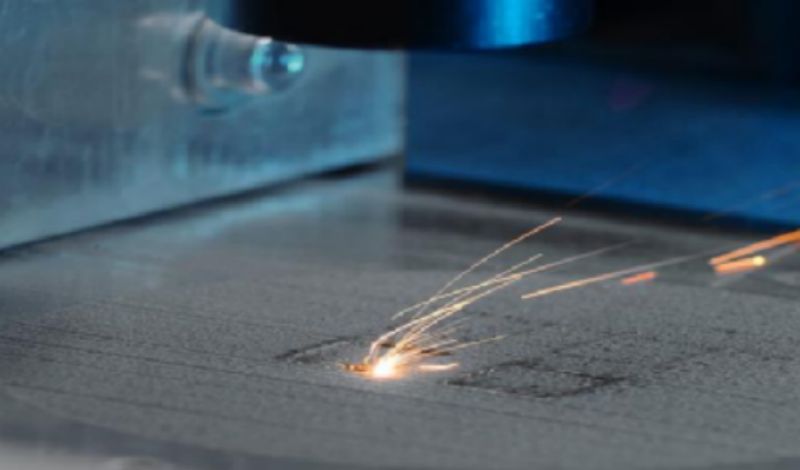

Nyob rau hauv xyoo tas los no, ua tsaug rau txoj kev loj hlob sai ntawm lub zog tshiab kev lag luam, laser welding tau nkag mus rau tag nrho cov tshiab zog kev lag luam vim nws ceev thiab ruaj khov zoo. Ntawm lawv, cov cuab yeej siv laser vuam suav rau qhov feem ntau ntawm cov ntawv thov hauv kev lag luam tag nrho lub zog tshiab.

Laser vuamtau sai sai dhau los ua thawj qhov kev xaiv hauv txhua qhov chaw ntawm lub neej vim nws qhov nrawm nrawm, qhov tob loj, thiab me me deformation. Los ntawm qhov chaw welds mus rau pob tw welds, tsim thiab foob welds,laser vuammuab unparalleled precision thiab tswj. Nws ua lub luag haujlwm tseem ceeb hauv kev tsim khoom thiab kev tsim khoom, suav nrog kev lag luam tub rog, kev kho mob, aerospace, 3C nws pib qhov chaw, cov tshuab ntawv hlau, lub zog tshiab thiab lwm yam kev lag luam.

Piv nrog rau lwm yam vuam thev naus laus zis, laser vuam muaj nws qhov tshwj xeeb zoo thiab qhov tsis zoo.

Qhov zoo:

1. Ceev ceev, qhov tob loj thiab me me deformation.

2. Vuam tuaj yeem ua tau ntawm qhov kub thiab txias lossis nyob rau hauv cov xwm txheej tshwj xeeb, thiab cov khoom siv vuam yog yooj yim. Piv txwv li, lub laser beam tsis drift nyob rau hauv ib tug electromagnetic teb. Lasers tuaj yeem welding hauv lub tshuab nqus tsev, huab cua lossis qee qhov chaw nkev, thiab tuaj yeem txuas cov khoom siv los ntawm iav los yog pob tshab rau lub teeb laser.

3. Nws tuaj yeem vuam cov ntaub ntawv refractory xws li titanium thiab quartz, thiab tuaj yeem vuam cov khoom sib txawv nrog cov txiaj ntsig zoo.

4. Tom qab lub laser tsom, lub zog ceev yog siab. Qhov sib piv tuaj yeem ncav cuag 5: 1, thiab tuaj yeem ncav cuag 10: 1 thaum vuam cov khoom siv hluav taws xob siab.

5. Micro vuam tuaj yeem ua tau. Tom qab lub laser beam tsom, ib qho chaw me me tuaj yeem tau txais thiab tuaj yeem muab tso rau qhov tseeb. Nws tuaj yeem siv rau kev sib dhos thiab vuam ntawm micro thiab me me workpieces kom ua tiav cov khoom siv ntau lawm.

6. Nws tuaj yeem vuam qhov nyuaj-rau-mus txog thiab ua haujlwm tsis sib cuag nrog qhov ntev-ntev vuam, nrog kev yooj yim heev. Tshwj xeeb tshaj yog nyob rau hauv xyoo tas los no, YAG laser ua tshuab tau txais kev siv tshuab fiber ntau kis tau tus mob, uas tau ua haujlwm laser vuam tshuab kom tau txais kev txhawb nqa ntau dua thiab siv.

7. Lub laser beam yog ib qho yooj yim rau kev sib cais nyob rau hauv lub sij hawm thiab qhov chaw, thiab ntau beams yuav ua tiav nyob rau hauv ntau qhov chaw ib txhij, muab tej yam kev mob rau ntau meej vuam.

Tsis zoo:

1. Kev sib dhos qhov tseeb ntawm lub workpiece yuav tsum siab, thiab txoj hauj lwm ntawm lub nqaj ntawm lub workpiece tsis tuaj yeem sib txawv heev. Qhov no yog vim hais tias lub laser qhov chaw loj tom qab tsom me me thiab cov weld seam yog nqaim, ua rau nws nyuaj rau ntxiv cov khoom siv hlau. Yog hais tias qhov kev sib dhos qhov tseeb ntawm lub workpiece los yog qhov chaw qhov tseeb ntawm lub nqaj tsis ua tau raws li qhov yuav tsum tau ua, qhov vuam tsis zoo yuav tshwm sim.

2. Tus nqi ntawm cov lasers thiab cov tshuab cuam tshuam yog siab, thiab kev nqis peev ib zaug yog loj.

Common laser vuam defectshauv kev tsim cov roj teeb lithium

1. Vuam porosity

Feem ntau tsis xws luag nyob rau hauvlaser vuamyog pores. Lub vuam molten pas dej ua ke yog tob thiab nqaim. Thaum lub sij hawm laser vuam txheej txheem, nitrogen invades lub molten pas dej ua ke los ntawm sab nraud. Thaum lub sij hawm txias thiab solidification txheej txheem ntawm hlau, solubility ntawm nitrogen txo nrog qhov kub thiab txias. Thaum lub pas dej molten hlau txias kom pib crystallize, lub solubility yuav poob sharply thiab dheev. Lub sijhawm no, cov pa roj ntau ntau yuav ua rau ua npuas. Yog hais tias lub floating ceev ntawm cov npuas yog tsawg tshaj li cov hlau crystallization ceev, pores yuav generated.

Hauv kev siv hauv kev lag luam roj teeb lithium, peb feem ntau pom tias qhov pores tshwj xeeb yuav tshwm sim thaum lub sij hawm vuam ntawm qhov zoo electrode, tab sis tsis tshua muaj tshwm sim thaum lub sij hawm vuam ntawm qhov tsis zoo electrode. Qhov no yog vim qhov zoo electrode yog ua los ntawm txhuas thiab qhov tsis zoo electrode yog ua los ntawm tooj liab. Thaum lub sij hawm welding, cov kua txhuas ntawm qhov chaw tau condensed ua ntej cov roj sab hauv tag nrho overflows, tiv thaiv cov roj los ntawm overflowing thiab tsim qhov loj thiab me. Me stomata.

Ntxiv rau qhov ua rau ntawm qhov pores tau hais los saum toj no, qhov pores kuj suav nrog huab cua sab nraum zoov, noo noo, roj saum npoo, thiab lwm yam. Tsis tas li ntawd, kev taw qhia thiab lub kaum sab xis ntawm nitrogen tshuab kuj tseem cuam tshuam rau kev tsim cov pores.

Yuav ua li cas kom txo tau qhov tshwm sim ntawm vuam pores?

Ua ntej, ua ntejvuam, cov roj stains thiab impurities nyob rau saum npoo ntawm cov khoom tuaj yuav tsum tau ntxuav nyob rau hauv lub sij hawm; Hauv kev tsim cov roj teeb lithium, kev tshuaj xyuas cov khoom tuaj yog txheej txheem tseem ceeb.

Qhov thib ob, lub shielding gas flow yuav tsum tau kho raws li tej yam xws li vuam ceev, lub zog, txoj hauj lwm, thiab lwm yam, thiab yuav tsum tsis txhob loj los yog me me. Lub tsho tiv thaiv lub siab yuav tsum tau hloov kho raws li cov yam ntxwv xws li lub zog laser thiab txoj haujlwm ua kom pom tseeb, thiab yuav tsum tsis txhob siab dhau lossis qis dhau. Cov duab ntawm lub tsho tiv thaiv lub tsho yuav tsum tau kho raws li cov duab, kev taw qhia thiab lwm yam ntawm cov vuam kom lub tsho tiv thaiv tuaj yeem sib npaug ntawm qhov chaw vuam.

Thib peb, tswj qhov kub, av noo thiab plua plav hauv huab cua hauv kev cob qhia. Lub ambient kub thiab av noo yuav cuam tshuam cov dej noo nyob rau saum npoo ntawm lub substrate thiab cov roj tiv thaiv, uas yuav cuam tshuam rau tiam thiab khiav ntawm dej vapor nyob rau hauv lub molten pas dej ua ke. Yog tias qhov ntsuas kub thiab av noo siab dhau lawm, yuav muaj cov dej noo ntau dhau ntawm lub substrate thiab cov roj tiv thaiv, ua kom muaj dej ntau ntau, ua rau lub qhov hws. Yog tias qhov ntsuas kub thiab av noo tsawg dhau, yuav muaj dej noo tsawg dhau ntawm qhov chaw ntawm lub substrate thiab hauv cov roj tiv thaiv, txo cov tiam ntawm cov dej vapor, yog li txo qhov pores; cia cov neeg ua haujlwm zoo txheeb xyuas lub hom phiaj tus nqi ntawm qhov kub, av noo thiab plua plav ntawm qhov chaw vuam.

Plaub, txoj kev viav vias viav vias yog siv los txo lossis tshem tawm qhov pores hauv laser tob tob vuam. Vim qhov sib ntxiv ntawm viav vias thaum vuam, lub viav vias reciprocating ntawm lub nqaj mus rau lub vuam seam ua rau rov qab remelting ntawm ib feem ntawm vuam seam, uas ua rau lub sij hawm nyob ntawm cov kua hlau nyob rau hauv lub vuam pas dej ua ke. Nyob rau tib lub sij hawm, lub deflection ntawm lub beam kuj nce lub tshav kub input rau ib cheeb tsam. Qhov sib piv ntawm qhov tob-rau-dav ntawm qhov vuam yog txo, uas yog qhov tsim nyog rau qhov tshwm sim ntawm npuas, yog li tshem tawm qhov pores. Ntawm qhov tod tes, lub viav vias ntawm lub nqaj ua rau lub qhov me me ua viav vias raws li, uas tuaj yeem muab lub zog nplawm rau lub vuam pas dej ua ke, ua kom cov convection thiab stirring ntawm vuam pas dej ua ke, thiab muaj txiaj ntsig zoo ntawm kev tshem tawm cov pores.

Thib tsib, cov mem tes zaus, cov mem tes zaus yog hais txog tus naj npawb ntawm cov pulses tawm los ntawm lub laser beam ib lub sij hawm, uas yuav cuam tshuam rau lub tshav kub input thiab tshav kub tsub kom nyob rau hauv lub molten pas dej ua ke, thiab ces cuam tshuam rau qhov kub thiab txias teb nyob rau hauv lub molten. pas dej ua ke. Yog hais tias cov mem tes zaus siab dhau lawm, nws yuav ua rau muaj cua sov ntau dhau ntawm lub pas dej molten, ua rau qhov kub ntawm lub pas dej molten siab dhau, ua rau cov hlau vapor los yog lwm yam khoom uas tsis hloov pauv ntawm qhov kub thiab txias, ua rau cov pores. Yog hais tias cov mem tes zaus tsawg dhau, nws yuav ua rau cov cua kub tsis txaus nyob rau hauv lub pas dej molten, ua rau qhov kub thiab txias ntawm lub pas dej molten tsawg dhau, txo qhov kev sib cais thiab khiav tawm ntawm cov pa roj, uas ua rau cov pores. Feem ntau hais lus, cov mem tes zaus yuav tsum tau xaiv nyob rau hauv ib qho kev tsim nyog raws li lub substrate thickness thiab laser zog, thiab tsis txhob siab dhau los yog tsawg dhau.

Vuam qhov (laser welding)

2. Weld spatter

Lub spatter generated thaum lub sij hawm welding txheej txheem, laser welding yuav cuam tshuam rau qhov zoo ntawm lub vuam, thiab yuav ua paug thiab puas lub lens. Kev ua haujlwm dav dav yog raws li hauv qab no: tom qab laser welding tiav, ntau cov hlau hais tshwm rau ntawm qhov chaw ntawm cov khoom lossis cov khoom ua haujlwm thiab ua raws li cov khoom siv lossis cov khoom ua haujlwm. Qhov kev ua tau zoo tshaj plaws yog thaum vuam hauv hom tiv thaiv lub ntsej muag ntawm lub galvanometer, yuav muaj tuab pits rau saum npoo, thiab cov pits no yog tshwm sim los ntawm vuam spatter. Tom qab lub sijhawm ntev, nws yooj yim los thaiv lub teeb, thiab yuav muaj teeb meem nrog vuam lub teeb, ua rau muaj teeb meem xws li tawg vuam thiab vuam virtual.

Dab tsi yog qhov ua rau txaws?

Ua ntej, lub hwj chim ceev, qhov ntau dua lub zog ntom, qhov yooj yim nws yog los tsim kom muaj, thiab lub ntsej muag yog ncaj qha rau lub hwj chim ntom ntom. Qhov no yog ib puas xyoo teeb meem. Tsawg kawg li tam sim no, kev lag luam tsis tuaj yeem daws qhov teeb meem ntawm kev txaws, thiab tsuas tuaj yeem hais tias nws tau txo qis me ntsis. Hauv kev lag luam roj teeb lithium, kev txaws yog qhov ua txhaum loj tshaj plaws ntawm cov roj teeb luv luv, tab sis nws tsis tuaj yeem daws qhov laj thawj. Qhov cuam tshuam ntawm spatter ntawm lub roj teeb tsuas yog txo los ntawm qhov pom ntawm kev tiv thaiv. Piv txwv li, ib lub voj voog ntawm cov chaw nres nkoj tshem tawm plua plav thiab cov npog tiv thaiv ntxiv nyob ib puag ncig ntawm qhov vuam, thiab cov kab ntawm cov riam cua tau ntxiv rau hauv cov voj voog kom tiv thaiv kev cuam tshuam ntawm spatter los yog puas tsuaj rau lub roj teeb. Kev puas tsuaj ib puag ncig, cov khoom thiab cov khoom siv nyob ib puag ncig ntawm qhov chaw nres tsheb vuam tuaj yeem hais tias tau siv tag nrho cov txhais tau tias.

Raws li kev daws qhov teeb meem spatter, nws tsuas tuaj yeem hais tau tias txo cov vuam zog pab txo qhov tawg. Txo qhov vuam ceev kuj tuaj yeem pab yog tias kev nkag mus tsis txaus. Tab sis nyob rau hauv qee qhov kev xav tau tshwj xeeb, nws muaj kev cuam tshuam me ntsis. Nws yog cov txheej txheem tib yam, cov tshuab sib txawv thiab cov khoom sib txawv ntawm cov khoom muaj qhov sib txawv ntawm qhov sib txawv kiag li. Yog li ntawd, muaj ib txoj cai uas tsis tau sau nyob rau hauv lub zog tshiab kev lag luam, ib txheej ntawm vuam tsis rau ib daim ntawm cov khoom.

Qhov thib ob, yog tias qhov chaw ntawm cov khoom ua tiav lossis cov khoom ua haujlwm tsis raug ntxuav, cov roj stains lossis cov pa phem yuav ua rau tawg loj heev. Nyob rau lub sijhawm no, qhov yooj yim tshaj plaws yog los ntxuav qhov chaw ntawm cov khoom ua tiav.

3. High reflectivity ntawm laser vuam

Feem ntau hais lus, kev xav txog siab yog hais txog qhov tseeb tias cov khoom siv ua haujlwm muaj qhov tsis zoo me me, qhov chaw du, thiab qhov nqus qis rau ze-infrared lasers, uas ua rau muaj ntau ntawm laser emissions, thiab vim tias feem ntau siv lasers. nyob rau hauv ntsug Vim yog cov khoom siv los yog me me ntawm inclination, lub teeb rov qab laser rov nkag mus rau lub taub hau tso zis, thiab txawm tias ib feem ntawm lub teeb rov qab yog txuas rau hauv lub zog xa hluav taws xob, thiab xa rov qab raws cov fiber ntau rau sab hauv. ntawm lub laser, ua rau cov khoom tseem ceeb hauv lub laser txuas ntxiv mus rau qhov kub thiab txias.

Thaum lub reflectivity siab dhau lawm thaum lub sij hawm laser vuam, cov nram qab no daws yuav tsum tau:

3.1 Siv cov tshuaj tiv thaiv kev cuam tshuam los yog kho qhov chaw ntawm cov khoom siv: txheej txheej ntawm cov khoom siv vuam nrog cov txheej tiv thaiv kev cuam tshuam tuaj yeem txo qhov kev cuam tshuam ntawm lub laser. Cov txheej no feem ntau yog cov khoom siv kho qhov muag tshwj xeeb uas tsis tshua muaj kev cuam tshuam uas absorbs laser zog es tsis txhob xav txog nws rov qab. Hauv qee cov txheej txheem, xws li cov khoom siv vuam tam sim no, kev sib txuas muag muag, thiab lwm yam, qhov saum npoo kuj tuaj yeem embossed.

3.2 Kho lub vuam lub kaum sab xis: Los ntawm kev kho lub vuam lub kaum sab xis, lub laser beam tuaj yeem tshwm sim ntawm cov khoom siv vuam ntawm lub kaum sab xis tsim nyog thiab txo qhov tshwm sim ntawm kev xav. Nquag, muaj qhov teeb meem laser beam perpendicularly rau saum npoo ntawm cov khoom yuav tsum tau welded yog ib txoj hauv kev zoo los txo qhov kev xav.

3.3 Ntxiv auxiliary absorbent: Thaum lub sij hawm vuam txheej txheem, ib co ntawm cov auxiliary absorbent, xws li hmoov los yog kua, yog ntxiv rau lub vuam. Cov absorbers no nqus laser zog thiab txo qhov kev xav. Qhov tsim nyog absorbent yuav tsum raug xaiv raws li cov khoom siv vuam tshwj xeeb thiab kev siv cov xwm txheej. Hauv kev lag luam roj teeb lithium, qhov no tsis zoo li.

3.4 Siv cov khoom siv kho qhov muag los xa cov laser: Yog tias ua tau, cov khoom siv fiber ntau tuaj yeem siv los xa cov laser mus rau qhov chaw vuam kom txo tau qhov cuam tshuam. Optical fibers tuaj yeem coj lub teeb laser mus rau qhov chaw vuam kom tsis txhob raug ncaj qha rau ntawm cov khoom siv vuam thiab txo qhov tshwm sim ntawm kev xav.

3.5 Kho laser tsis: Los ntawm kev kho qhov tsis xws li laser fais fab, focal ntev, thiab focal txoj kab uas hla, kev faib ntawm lub zog laser tuaj yeem tswj tau thiab kev cuam tshuam tuaj yeem txo. Rau qee cov ntaub ntawv muaj kev cuam tshuam, txo lub zog laser yuav yog ib txoj hauv kev zoo los txo qhov kev xav.

3.6 Siv lub nqaj splitter: Lub nqaj splitter tuaj yeem coj ib feem ntawm lub zog laser rau hauv cov cuab yeej nqus, yog li txo qhov tshwm sim ntawm kev xav. Beam splitting li feem ntau muaj cov khoom siv kho qhov muag thiab cov khoom siv absorbers, thiab los ntawm kev xaiv cov khoom tsim nyog thiab kho cov txheej txheem ntawm cov cuab yeej, qhov kev xav tau qis dua tuaj yeem ua tiav.

4. Vuam undercut

Hauv cov txheej txheem tsim cov roj teeb lithium, cov txheej txheem twg yuav ua rau qis dua? Vim li cas undercutting tshwm sim? Cia peb tsom xam.

Undercut, feem ntau cov khoom siv vuam tsis zoo sib xyaw ua ke, qhov sib txawv loj dhau los yog qhov zawj tshwm, qhov tob thiab qhov dav yog qhov tseem ceeb tshaj 0.5 hli, tag nrho ntev yog ntau dua 10% ntawm qhov ntev vuam, lossis ntau dua cov txheej txheem khoom tus qauv thov ntev.

Nyob rau hauv tag nrho cov lithium roj teeb raug txheej txheem, undercutting yog feem ntau yuav tshwm sim, thiab nws yog feem ntau faib nyob rau hauv lub sealing pre-welding thiab vuam ntawm lub cylindrical npog phaj thiab sealing pre-welding thiab vuam ntawm lub square aluminium plhaub npog phaj. Qhov laj thawj tseem ceeb yog vim li cas lub sealing npog phaj yuav tsum tau koom tes nrog lub plhaub rau Vuam, cov txheej txheem sib txuam ntawm lub sealing npog phaj thiab lub plhaub yog feem ntau ua rau weld khoob, grooves, vau, thiab lwm yam., yog li nws yog tshwj xeeb tshaj yog rau undercuts. .

Yog li dab tsi ua rau undercutting?

Yog tias qhov vuam ceev nrawm dhau, cov kua hlau tom qab lub qhov me me taw rau qhov nruab nrab ntawm qhov vuam yuav tsis muaj sij hawm rov xa rov qab, ua rau muaj kev sib koom ua ke thiab qis qis ntawm ob sab ntawm lub vuam. Nyob rau hauv kev pom ntawm qhov teeb meem saum toj no, peb yuav tsum tau optimize lub vuam tsis. Txhawm rau muab nws yooj yim, nws yog qhov kev sim rov qab los txheeb xyuas ntau yam tsis muaj, thiab ua DOE kom txog thaum pom qhov tsim nyog.

2. Ntau qhov sib txuas ntawm vuam, zawj, qhov sib tsoo, thiab lwm yam ntawm cov khoom siv vuam yuav txo cov hlau molten filling qhov khoob, ua rau undercuts yuav tshwm sim. Qhov no yog cov lus nug ntawm cov khoom siv thiab cov khoom siv raw. Txawm hais tias cov khoom siv vuam vuam ua tau raws li cov khoom yuav tsum tau ua ntawm peb cov txheej txheem, seb cov khoom siv puas ua tau raws li qhov yuav tsum tau ua, thiab lwm yam. Qhov kev coj ua ib txwm tsim txom thiab ntaus cov neeg muab khoom thiab cov neeg ua haujlwm ntawm cov khoom siv.

3. Yog hais tias lub zog poob sai heev ntawm qhov kawg ntawm laser vuam, lub qhov me me yuav vau, ua rau hauv zos undercutting. Kev sib raug zoo ntawm lub zog thiab ceev tuaj yeem tiv thaiv kev tsim ntawm undercuts. Raws li cov lus qub hais mus, rov ua qhov kev sim, txheeb xyuas ntau yam tsis muaj, thiab txuas ntxiv DOE kom txog thaum koj pom qhov tsis raug.

5. Weld center collapse

Yog tias qhov vuam ceev qeeb, lub pas dej molten yuav loj dua thiab dav dua, ua rau cov hlau molten ntau dua. Qhov no tuaj yeem ua rau kev tswj qhov nro nyuaj. Thaum cov hlau molten hnyav dhau lawm, qhov nruab nrab ntawm cov weld yuav tog thiab tsim cov dips thiab pits. Hauv qhov no, lub zog ntom ntom yuav tsum raug txo kom tsim nyog los tiv thaiv lub pas dej tawg.

Hauv lwm qhov xwm txheej, qhov sib txawv ntawm qhov vuam tsuas yog tsim lub cev qhuav dej tsis ua rau perforation. Qhov no yog undoubtedly ib qho teeb meem ntawm cov khoom siv xovxwm haum.

Kev nkag siab zoo ntawm qhov tsis xws luag tuaj yeem tshwm sim thaum lub sij hawm laser vuam thiab qhov ua rau ntawm qhov tsis xws luag tso cai rau ntau lub hom phiaj los daws cov teeb meem vuam txawv txav.

6. Weld tawg

Cov kab nrib pleb uas tshwm sim thaum lub sij hawm txuas ntxiv laser vuam yog feem ntau thermal tawg, xws li siv lead ua tawg thiab liquefaction tawg. Qhov laj thawj tseem ceeb ntawm cov kab nrib pleb yog qhov loj shrinkage rog tsim los ntawm cov vuam ua ntej nws tag nrho solidifies.

Kuj tseem muaj cov laj thawj hauv qab no rau cov kab nrib pleb hauv laser vuam:

1. Kev tsim vuam tsis tsim nyog: kev tsim tsis zoo ntawm cov duab geometry thiab qhov loj ntawm cov vuam yuav ua rau vuam kev nyuaj siab, yog li ua rau tawg. Txoj kev daws teeb meem yog txhawm rau txhim kho qhov kev tsim vuam kom tsis txhob vuam kev nyuaj siab. Koj tuaj yeem siv qhov tsim nyog offset welds, hloov qhov vuam zoo, thiab lwm yam.

2. Kev tsis sib haum ntawm cov vuam tsis sib xws: kev xaiv tsis zoo ntawm cov vuam tsis zoo, xws li vuam ceev heev, lub zog siab dhau, thiab lwm yam, tuaj yeem ua rau qhov kub tsis sib xws hauv qhov chaw vuam, ua rau cov vuam loj thiab tawg. Qhov kev daws teeb meem yog los kho cov vuam tsis sib xws kom haum rau cov khoom siv tshwj xeeb thiab vuam tej yam kev mob.

3. Kev npaj tsis zoo ntawm qhov chaw vuam: tsis ua kom zoo thiab ua ntej kho qhov vuam nto ua ntej vuam, xws li tshem tawm oxides, roj, thiab lwm yam, yuav cuam tshuam rau qhov zoo thiab lub zog ntawm vuam thiab yooj yim ua rau tawg. Qhov kev daws teeb meem yog kom huv thiab ua ntej kho qhov chaw vuam kom paub meej tias cov impurities thiab cov kab mob hauv qhov vuam tau zoo.

4. Kev tswj tsis zoo ntawm vuam cov khoom siv hluav taws xob tsis zoo: Kev tswj tsis zoo ntawm cov khoom siv hluav taws xob thaum lub sij hawm vuam, xws li qhov kub thiab txias thaum lub sij hawm vuam, qhov tsis zoo ntawm cov txheej txheem vuam, thiab lwm yam, yuav ua rau muaj kev hloov pauv ntawm cov qauv ntawm qhov vuam, ua rau tawg. . Qhov kev daws teeb meem yog los tswj qhov kub thiab txias tus nqi thaum lub sij hawm vuam kom tsis txhob overheating thiab ceev txias.

5. Kev ntxhov siab tsis txaus: Kev kho kev ntxhov siab tsis txaus tom qab vuam yuav ua rau muaj kev ntxhov siab tsis txaus nyob rau hauv qhov chaw welded, uas yuav yooj yim ua rau tawg. Txoj kev daws teeb meem yog ua kom muaj kev kho kom zoo rau kev ntxhov siab tom qab vuam, xws li kev kho cua sov lossis kev vibration kho (qhov laj thawj tseem ceeb).

Raws li kev tsim cov txheej txheem ntawm cov roj teeb lithium, cov txheej txheem twg yuav ua rau tawg?

Feem ntau, cov kab nrib pleb yuav tshwm sim thaum lub sij hawm sib khi, xws li sealing vuam ntawm cylindrical steel shells lossis txhuas plhaub, sealing vuam ntawm square aluminium plhaub, thiab lwm yam. Tsis tas li ntawd, thaum lub sij hawm ntim cov txheej txheem, qhov vuam ntawm cov khoom siv tam sim no kuj yog ib qho yooj yim. mus tawg.

Tau kawg, peb kuj tuaj yeem siv cov xaim xaim, preheating lossis lwm txoj hauv kev los txo lossis tshem tawm cov kab nrib pleb.

Post lub sij hawm: Sep-01-2023