Muaj neeg hlaus yog siv dav hauv kev tsim khoom, xws li kev tsim tsheb, khoom siv hluav taws xob, khoom noj khoom haus, thiab lwm yam. Lawv tuaj yeem hloov cov kev ua haujlwm rov ua dua tshiab thiab yog cov tshuab uas cia siab rau lawv tus kheej lub zog thiab kev tswj kom ua tiav ntau yam haujlwm. Nws tuaj yeem tiv taus tib neeg cov lus txib thiab tuaj yeem ua haujlwm raws li cov kev pabcuam ua ntej. Tam sim no peb tham txog cov ntsiab lus tseem ceeb ntawmmuaj neeg hlaus.

1. Kawm

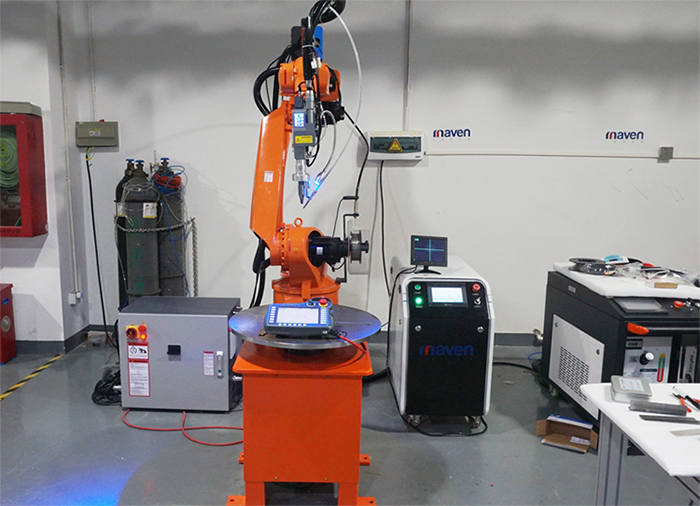

Lub ntsiab machinery yog lub hauv paus tshuab thiab lub actuating mechanism, nrog rau lub caj npab loj, forearm, dab teg thiab tes, uas yog ib tug multi-degree-of-freedom mechanical system. Qee cov neeg hlau kuj muaj cov txheej txheem taug kev.Muaj neeg hlausmuaj 6 qib kev ywj pheej lossis ntau dua. Lub dab teg feem ntau muaj 1 txog 3 degrees ntawm kev ywj pheej ntawm kev txav mus los.

2. Tsav system

Qhov kev tsav tsheb ntawmmuaj neeg hlausmuab faib ua peb pawg raws li lub zog qhov chaw: hydraulic, pneumatic thiab hluav taws xob. Peb hom no tseem tuaj yeem muab tso ua ke rau hauv kev sib xyaw tsav tsheb raws li qhov yuav tsum tau ua. Los yog indirectly tsav los ntawm cov neeg kho tshuab kis tau tus mob mechanisms xws li synchronous siv, iav tsheb ciav hlau, thiab iav. Lub kaw lus tsav tsheb muaj lub tshuab hluav taws xob thiab lub tshuab xa hluav taws xob, uas yog siv los siv cov kev coj ua ntawm lub tshuab. Txhua yam ntawm peb hom kev tsav tsheb pib muaj nws tus yam ntxwv. Lub ntsiab tam sim no yog lub zog tsav hluav taws xob. Vim tsis tshua muaj inertia, lub zog loj AC thiab DC servo motors thiab lawv cov kev txhawb nqa servo drives (AC zaus converters, DC mem tes dav modulators) tau dav siv. Hom kab ke no tsis xav tau lub zog hloov pauv, siv tau yooj yim, thiab muaj kev tswj hwm zoo. Feem ntau cov motors xav tau ib tug me me kis mechanism: ib tug reducer. Nws cov hniav siv lub iav ceev converter los txo tus naj npawb ntawm rov qab rotations ntawm lub cev muaj zog mus rau qhov yuav tsum tau tus naj npawb ntawm rov qab rotations thiab tau txais ib tug loj torque ntaus ntawv, yog li txo qhov ceev thiab nce lub torque. Thaum lub load loj, lub servo lub cev muaj zog yog qhov muag tsis pom Lub zog yog tus nqi zoo heev, thiab cov zis torque tuaj yeem nce ntxiv los ntawm tus reducer nyob rau hauv ib qho kev ceev ceev. Servo motors yog nquag ua kom sov thiab tsis tshua muaj kev vibration thaum ua haujlwm ntawm qhov tsawg zaus. Kev ua haujlwm ntev thiab rov ua haujlwm tsis zoo rau kev ua haujlwm kom raug thiab txhim khu kev qha. Lub hav zoov ntawm precision txo lub cev muaj zog tso cai rau lub servo lub cev muaj zog ua hauj lwm ntawm ib tug haum ceev, ntxiv dag zog rau lub rigidity ntawm lub tshuab lub cev thiab outputting ntau dua torque. Niaj hnub no muaj ob lub ntsiab reducers: harmonic reducer thiab RV reducer.

3.Control system

Covneeg hlau tswj systemyog lub hlwb ntawm cov neeg hlau thiab lub ntsiab tseem ceeb uas txiav txim siab txog kev ua haujlwm thiab kev ua haujlwm ntawm tus neeg hlau. Lub kaw lus tswj tau xa cov lus txib mus rau lub kaw lus tsav tsheb thiab kev ua tiav mechanism raws li qhov kev pab cuam nkag, thiab tswj lawv. Lub luag haujlwm tseem ceeb ntawmmuaj neeg hlau tswj technology yog los tswj ntau yam kev ua ub no, posture thiab trajectory, thiab ua lub sij hawm ntawmmuaj neeg hlaus hauv qhov chaw ua haujlwm. Nws muaj cov yam ntxwv ntawm kev ua haujlwm yooj yim, software menu ua haujlwm, tus phooj ywg zoo tib neeg-khoos phis tawj sib cuam tshuam, kev ua haujlwm hauv online prompts thiab siv tau yooj yim. Lub tshuab tswj hwm yog lub hauv paus ntawm cov neeg hlau, thiab cov tuam txhab txawv teb chaws cuam tshuam raug kaw rau peb qhov kev sim. Nyob rau hauv xyoo tas los no, nrog kev txhim kho ntawm microelectronics thev naus laus zis, kev ua haujlwm ntawm microprocessors tau dhau los ua siab dua thiab siab dua, thiab tus nqi tau pheej yig dua thiab pheej yig dua. Tam sim no, 32-ntsis microprocessors raug nqi 1-2 US las tau tshwm sim hauv khw. Tus nqi tsim nyog microprocessors tau coj txoj hauv kev txhim kho tshiab rau cov neeg hlau maub los, ua rau nws muaj peev xwm tsim tau tus nqi qis, kev ua haujlwm siab ntawm cov neeg hlau. Txhawm rau ua kom lub kaw lus muaj peev xwm ua tau zoo thiab khaws cia, cov neeg hlau tswj tam sim no feem ntau yog tsim los ntawm cov haib ARM series, DSP series, POWERPC series, Intel series thiab lwm yam chips. Txij li cov kev ua haujlwm thiab kev ua haujlwm ntawm cov khoom siv dav dav uas twb muaj lawm tsis tuaj yeem ua tau raws li qhov yuav tsum tau muaj ntawm qee lub tshuab neeg hlau hais txog tus nqi, kev ua haujlwm, kev sib koom ua ke thiab kev sib txuas, qhov no tau ua rau qhov kev thov rau SoC (System on Chip) thev naus laus zis hauv cov tshuab neeg hlau. Lub processor yog kev koom ua ke nrog cov kev sib txuas uas yuav tsum tau ua, uas tuaj yeem ua kom yooj yim rau kev tsim cov kab ke peripheral circuits, txo qhov system loj, thiab txo cov nqi. Piv txwv li, Actel integrates NEOS lossis ARM7 processor cores rau hauv nws cov khoom FPGA los ua tiav SoC system. Nyob rau hauv cov nqe lus ntawm robots technology controllers, nws cov kev tshawb fawb yog mas concentrated nyob rau hauv lub tebchaws United States thiab Nyiv, thiab muaj mature cov khoom, xws li cov American DELTATAU Company, Nyiv lub Pengli Co., Ltd., thiab lwm yam. Nws cov motion controller siv DSP technology raws li nws. core thiab adopts PC-raws li qhib qauv. 4. End effector Qhov kawg effector yog ib feem txuas nrog lub xeem sib koom ua ke ntawm tus manipulator. Nws feem ntau yog siv los tuav cov khoom, txuas nrog lwm cov txheej txheem thiab ua cov haujlwm uas yuav tsum tau ua. Robot manufacturers feem ntau tsis tsim los yog muag kawg effectors; Feem ntau, lawv tsuas yog muab ib qho yooj yim gripper. Feem ntau qhov kawg effector yog ntsia rau ntawm 6-axis flange ntawm cov neeg hlau kom ua tiav cov haujlwm hauv ib puag ncig, xws li vuam, pleev xim, gluing, thiab qhov chaw thauj khoom thiab tshem tawm, uas yog cov haujlwm uas yuav tsum tau ua kom tiav.

Txheej txheem cej luam ntawm servo motors Tus neeg tsav tsheb servo, tseem hu ua "servo maub los" thiab "servo amplifier", yog tus maub los siv los tswj servo motors. Nws muaj nuj nqi zoo ib yam li cov zaus converter ntawm AC motors zoo tib yam, thiab nws yog ib feem ntawm lub servo system. Feem ntau, lub servo lub cev muaj zog yog tswj los ntawm peb txoj kev: txoj hauj lwm, ceev thiab torque kom ua tiav high-precision positioning ntawm lub kis tau tus mob system.

1. Kev faib tawm ntawm servo motors Nws muab faib ua ob pawg: DC thiab AC servo motors.

AC servo motors tau muab faib ua asynchronous servo motors thiab synchronous servo motors. Tam sim no, AC systems tau maj mam hloov DC systems. Piv nrog rau DC systems, AC servo motors muaj qhov zoo ntawm kev ntseeg siab, zoo cua sov dissipation, me me lub sij hawm ntawm inertia, thiab muaj peev xwm ua hauj lwm nyob rau hauv siab siab. Vim tias tsis muaj txhuam thiab lub kauj tsav, lub AC servo system kuj dhau los ua ib qho tsis siv neeg servo, thiab cov motors siv nyob rau hauv nws yog tawb-hom asynchronous motors thiab cov hlau nplaum ruaj khov synchronous motors nrog cov qauv brushless. 1) DC servo motors muab faib ua txhuam thiab txhuam tsis siv neeg

①Brushed motors muaj tus nqi qis, cov qauv yooj yim, pib lub zog loj, ntau yam ceev, kev tswj tau yooj yim, yuav tsum muaj kev saib xyuas, tab sis yooj yim los tswj (hloov cov txhuam hniav), tsim hluav taws xob cuam tshuam, muaj cov kev cai ntawm kev siv ib puag ncig, thiab feem ntau yog siv rau tus nqi tswj Sensitive general industrial thiab civil xwm txheej;

②Brushless motors yog qhov me me thiab lub teeb hauv qhov hnyav, nrog cov zis loj thiab cov lus teb ceev. Lawv muaj kev kub ceev thiab me me inertia, ruaj khov torque thiab du rotation. Kev tswj yog complex thiab ntse. Txoj kev hloov hluav taws xob hloov pauv hloov tau. Nws tuaj yeem hloov pauv nrog square yoj lossis sine yoj. Lub cev muaj zog tsis muaj kev saib xyuas thiab ua haujlwm zoo. Kev txuag hluav taws xob, hluav taws xob me me hluav taws xob, qhov kub tsis tshua muaj siab thiab lub neej ntev, haum rau ntau qhov chaw.

2. Cov yam ntxwv ntawm ntau hom servo motors

1) Qhov zoo thiab qhov tsis zoo ntawm DC servo lub cev muaj zog Qhov zoo: kev tswj ceev ceev, lub zog hnyav heev thiab cov yam ntxwv ceev, yooj yim tswj txoj cai, siv tau yooj yim, thiab pheej yig tus nqi. Disadvantages: txhuam commutation, ceev txwv, ntxiv tiv thaiv, tiam ntawm hnav hais (tsis haum rau plua plav-dawb thiab explosive ib puag ncig)

2) Qhov zoo thiab qhov tsis zoo ntawm AC servo lub cev muaj zog Qhov zoo: cov yam ntxwv tswj kev ceev ceev, kev tswj tau zoo nyob rau hauv tag nrho cov ceev ntau yam, yuav luag tsis muaj oscillation, high efficiency ntawm ntau tshaj 90%, tsawg tshav kub tiam, high-ceev tswj, high-precision txoj hauj lwm tswj (nyob ntawm tus encoder raug), rated Kev khiav hauj lwm hauv cheeb tsam tsis pub dhau, nws tuaj yeem ua tiav lub zog tas li, tsis tshua muaj zog, tsis muaj suab nrov, tsis muaj txhuam, thiab tsis muaj kev saib xyuas (tsim rau qhov chaw tsis muaj plua plav thiab tawg). Qhov tsis zoo: Kev tswj xyuas yog qhov nyuaj dua, tus tsav tsheb tsis xav tau hloov kho ntawm qhov chaw thiab PID tsis raug txiav txim siab, thiab yuav tsum muaj kev sib txuas ntxiv. Tam sim no, mainstream servo drives siv cov teeb liab digital processors (DSP) ua tus tswj core, uas tuaj yeem siv cov txheej txheem tswj kev sib tw thiab ua tiav digitization, networking thiab txawj ntse. Cov cuab yeej hluav taws xob feem ntau siv cov tsav hluav taws xob tsim nrog cov khoom siv hluav taws xob ntse (IPM) ua lub hauv paus. Lub IPM sib xyaw ua ke ntawm cov tsav hluav taws xob thiab muaj qhov tsis raug thiab tiv thaiv circuits xws li overvoltage, overcurrent, overheating, thiab undervoltage. Software kuj ntxiv rau lub ntsiab Circuit Court. Pib Circuit Court kom txo tau qhov cuam tshuam ntawm cov txheej txheem pib ntawm tus tsav tsheb. Lub zog tsav lub zog ua ntej kho cov tswv yim peb-theem fais fab lossis lub zog hluav taws xob los ntawm peb-theem puv-bridge rectifier circuit kom tau txais cov khoom siv ncaj qha. Lub rectified peb-theem fais fab lossis lub zog loj yog tom qab ntawd hloov mus rau zaus los ntawm peb-theem sinusoidal PWM voltage inverter los tsav peb-theem mus tas li hlau nplaum synchronous AC servo lub cev muaj zog. Tag nrho cov txheej txheem ntawm lub zog tsav tsheb tuaj yeem hais tau yooj yim yog AC-DC-AC txheej txheem. Lub ntsiab topological Circuit Court ntawm lub rectifier unit (AC-DC) yog peb-theem tag nrho-bridge uncontrolled rectifier circuit.

Kev pom ntawm lub teeb pom kev sib haum xeeb Nws coj lub tuam txhab Nyij Pooj Nabtesco 6-7 xyoo los ntawm kev tawm tswv yim RV tsim nyob rau hauv thaum ntxov 1980s kom ua tiav ib qho tseem ceeb ntawm kev tshawb fawb RV reducer hauv 1986; thiab Nantong Zhenkang thiab Hengfengtai, uas yog thawj zaug tsim cov txiaj ntsig hauv Suav teb, kuj tau siv sijhawm. 6-8 xyoo. Nws puas txhais tau tias peb cov lag luam hauv zos tsis muaj sijhawm? Qhov xwm zoo yog tias tom qab ob peb xyoos ntawm kev xa tawm, Tuam Tshoj cov tuam txhab thaum kawg tau ua qee qhov kev tawg.

*Cov tshooj no yog luam tawm los ntawm Is Taws Nem, thov hu rau peb kom tshem tawm kev ua txhaum cai.

Post lub sij hawm: Sep-15-2023