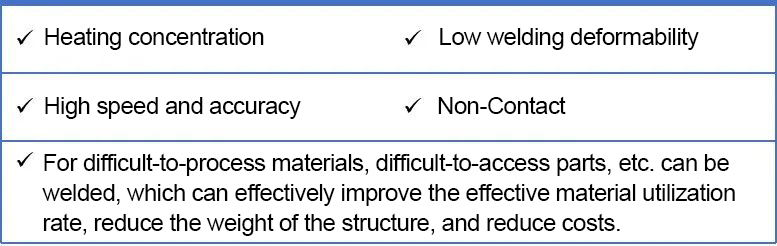

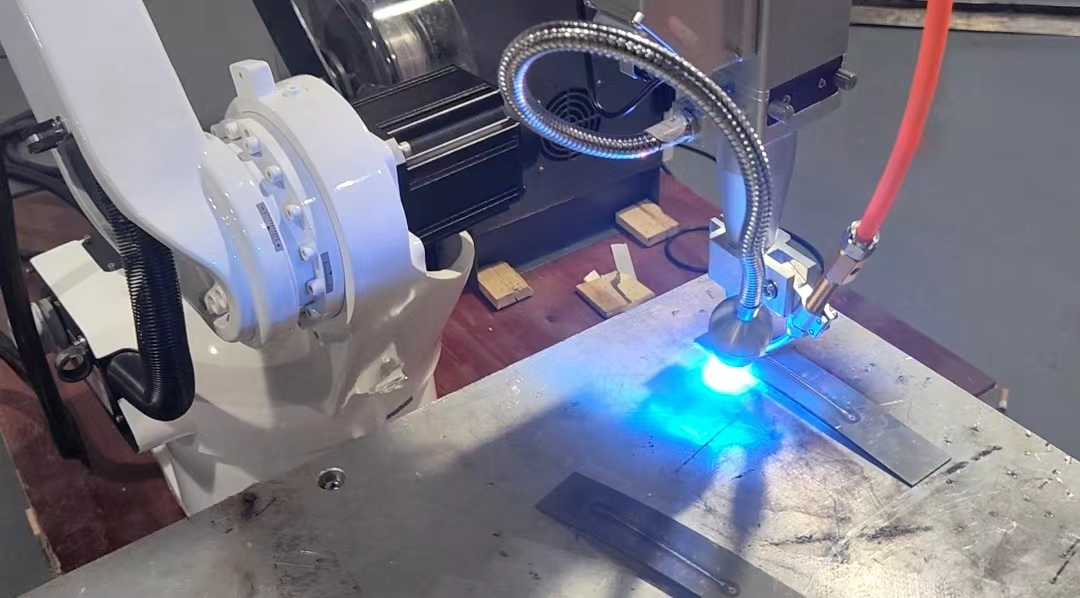

Laser sib koom tshuab, los yog laser vuam tshuab, siv lub zog loj laser beam tsom thiab tswj cov irradiation ntawm cov khoom nto, thiab cov khoom nto absorbs lub zog laser thiab converts nws mus rau hauv tshav kub zog, ua rau cov khoom nyob rau hauv lub zos kub thiab yaj. , ua raws li qhov txias thiab solidification kom ua tiav kev sib koom ua ke ntawm homogeneous lossis cov khoom sib txawv. Lub laser vuam txheej txheem yuav tsum tau ib tug laser zog ceev ntawm 104rau 108W / cm2. Piv rau cov txheej txheem vuam tsoos, laser vuam muaj qhov zoo hauv qab no.

Laser sib koom tshuab, los yog laser vuam tshuab, siv lub zog loj laser beam tsom thiab tswj cov irradiation ntawm cov khoom nto, thiab cov khoom nto absorbs lub zog laser thiab converts nws mus rau hauv tshav kub zog, ua rau cov khoom nyob rau hauv lub zos kub thiab yaj. , ua raws li qhov txias thiab solidification kom ua tiav kev sib koom ua ke ntawm homogeneous lossis cov khoom sib txawv. Lub laser vuam txheej txheem yuav tsum tau ib tug laser zog ceev ntawm 104rau 108W / cm2. Piv rau cov txheej txheem vuam tsoos, laser vuam muaj qhov zoo hauv qab no.

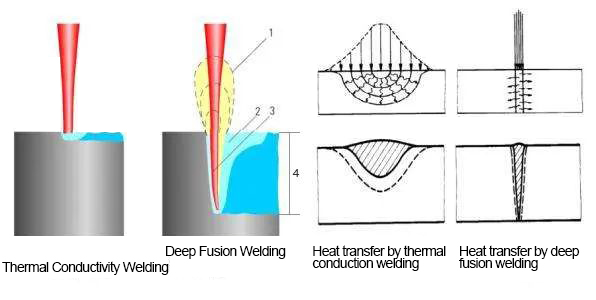

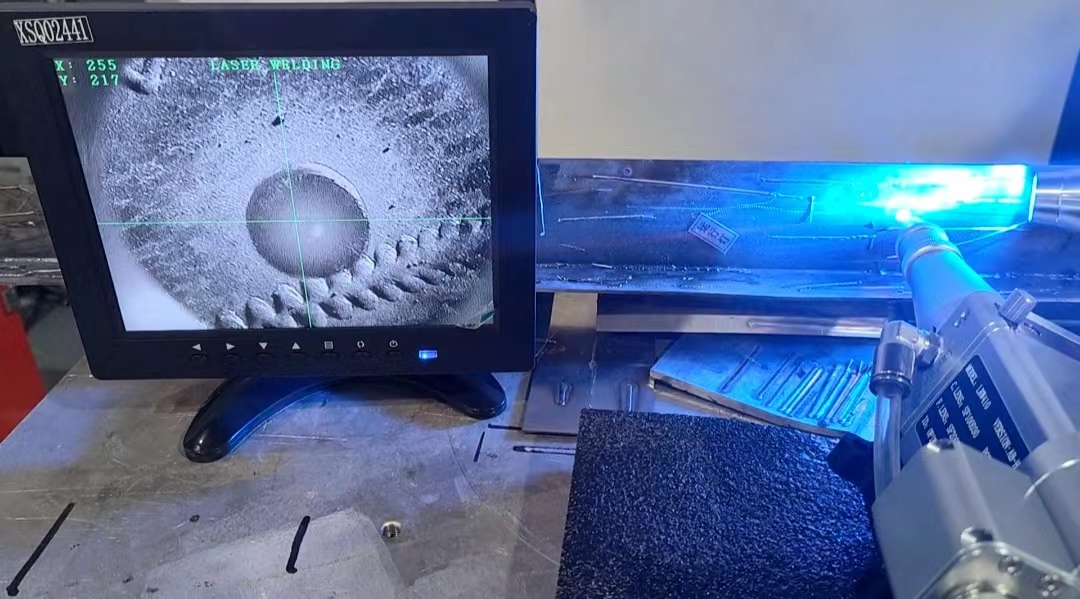

1-plasma huab, 2-melting khoom, 3-keyhole, 4-qhov tob ntawm fusion

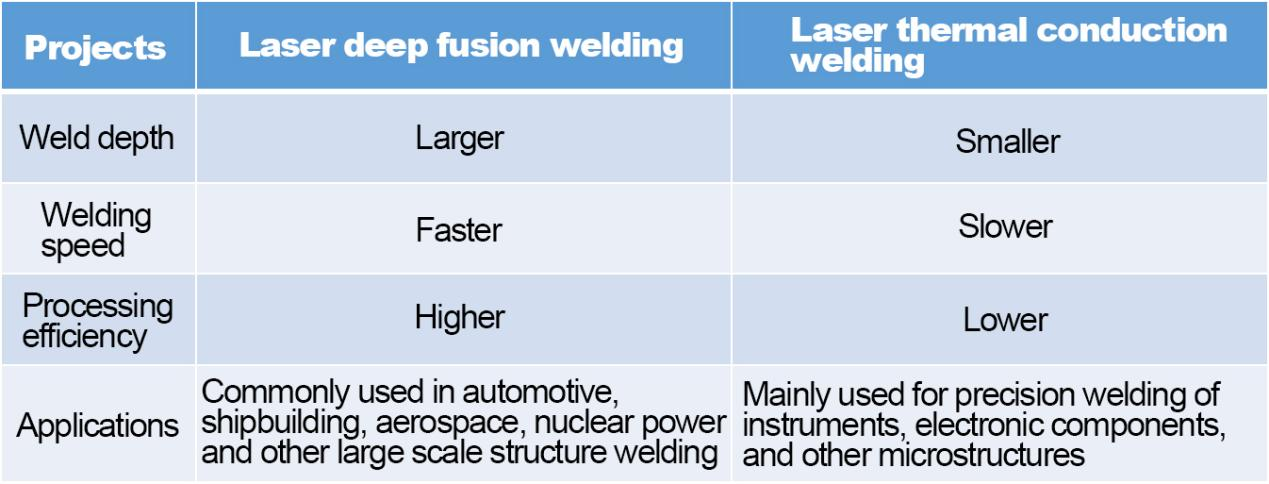

Vim yog qhov muaj nyob ntawm lub qhov tseem ceeb, lub laser beam, tom qab irradiating sab hauv ntawm lub qhov tseem ceeb, yuav ua rau kom lub nqus ntawm lub laser los ntawm cov khoom thiab txhawb kev tsim ntawm lub pas dej ua ke molten tom qab tawg thiab lwm yam teebmeem, ob txoj kev vuam yog muab piv. raws li nram no.

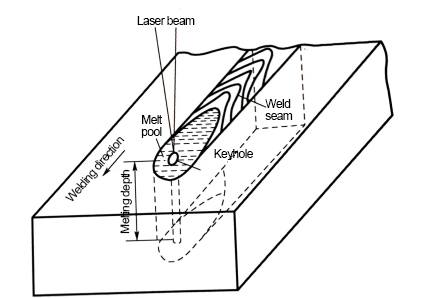

Daim duab saum toj no muab cov txheej txheem laser vuam ntawm tib cov khoom thiab tib lub teeb ci, lub zog hloov tshuab tsuas yog ua los ntawm lub qhov tseem ceeb, lub qhov tseem ceeb thiab cov hlau molten nyob ze ntawm phab ntsa ntawm lub qhov txav nrog kev ua ntej ntawm lub laser beam, cov hlau molten txav lub qhov tseem ceeb kom deb ntawm cov huab cua sab laug rau sau thiab tom qab condensation, tsim ib qho weld seam.

Yog tias cov khoom yuav tsum tau welded yog cov hlau tsis sib xws, qhov muaj qhov sib txawv ntawm cov khoom siv thermal yuav muaj kev cuam tshuam zoo rau cov txheej txheem vuam, xws li qhov sib txawv ntawm cov ntsiab lus melting, thermal conductivity, lub peev xwm kub tshwj xeeb, thiab nthuav coefficients ntawm cov khoom sib txawv, ua rau nyob rau hauv welding kev nyuaj siab, vuam deformation, thiab kev hloov nyob rau hauv lub crystallization tej yam kev mob ntawm welded sib koom hlau, ua rau ib tug txo nyob rau hauv lub mechanical zog ntawm lub weld.

Yog li ntawd, raws li cov yam ntxwv sib txawv ntawm qhov chaw vuam, cov txheej txheem vuam tau tsim laser muab tub lim vuam, laser brazing, dual-beam laser vuam, laser sib txuas vuam, thiab lwm yam.

Laser Hlau Filling Vuam

Nyob rau hauv cov txheej txheem laser vuam ntawm txhuas, titanium thiab tooj liab alloys, vim qhov tsis haum ntawm lub teeb laser (<10%) hauv cov ntaub ntawv no, cov duab tsim cov ntshav muaj qee qhov thaiv ntawm lub teeb laser, yog li nws yooj yim rau kev tawg thiab tawg. coj mus rau tiam ntawm qhov tsis xws luag xws li porosity thiab tawg. Tsis tas li ntawd, qhov vuam zoo kuj tseem cuam tshuam thaum qhov sib txawv ntawm cov khoom ua haujlwm loj dua li qhov chaw ntawm txoj kab uas hla thaum lub phaj nyias nyias sputtering.

Hauv kev daws cov teeb meem saum toj no, qhov txiaj ntsig zoo dua tuaj yeem tau txais los ntawm kev siv cov khoom muab tub lim. Cov muab tub lim tuaj yeem yog hlau lossis hmoov, los yog siv cov txheej txheem ua ntej. Vim qhov me me tsom qhov chaw, lub vuam yuav nqaim thiab muaj me ntsis convex zoo nyob rau saum npoo tom qab siv cov khoom muab tub lim.

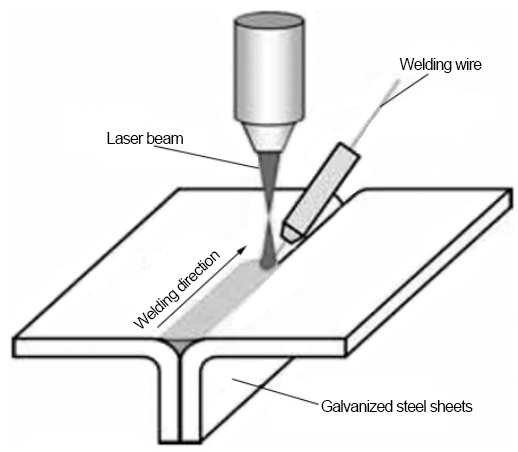

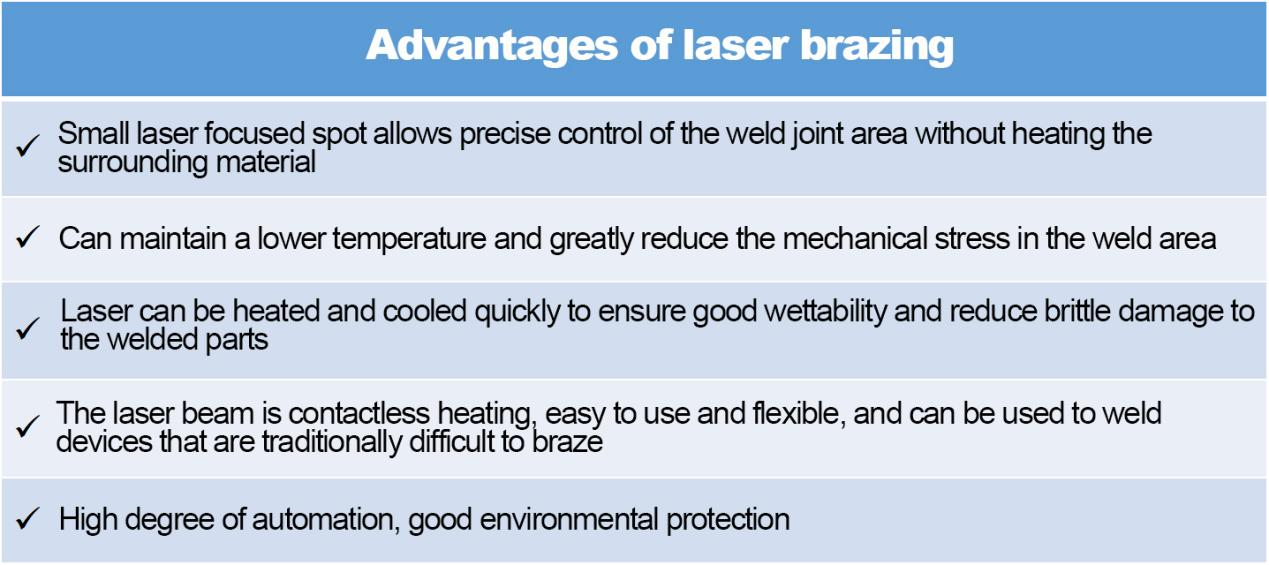

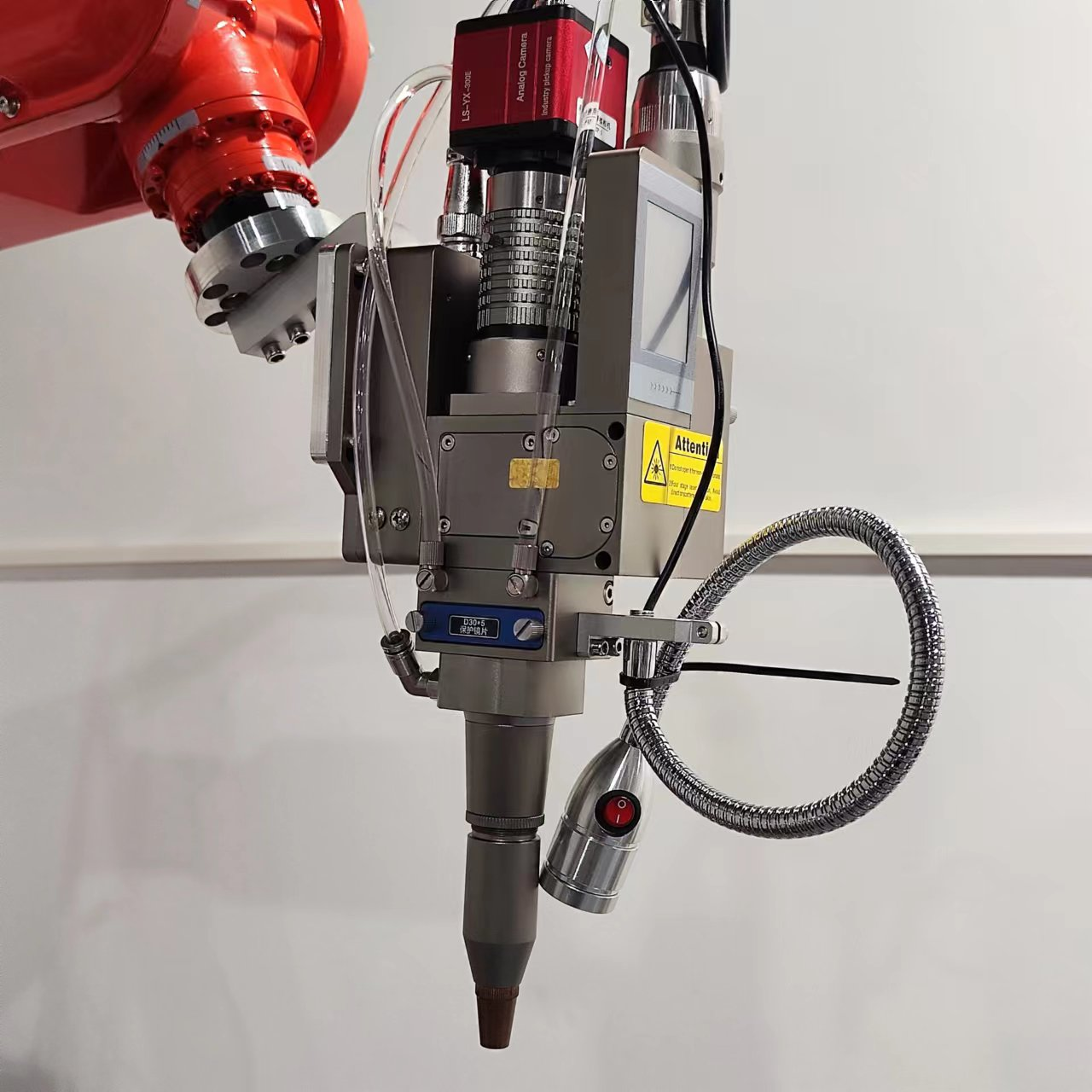

Laser Brazing

Tsis zoo li fusion welding, uas melts ob qhov chaw welded tib lub sijhawm, brazing ntxiv cov khoom muab tub lim nrog lub ntsiab lus qis dua li cov khoom siv hauv qhov chaw vuam, melts cov khoom muab tub lim los sau qhov sib txawv ntawm qhov kub qis dua li cov khoom siv melting. taw tes thiab siab dua cov khoom muab tub lim lub melting point, thiab ces condenses los ua ib tug khoom weld.

Brazing yog tsim rau cov khoom siv hluav taws xob kub-rhiab microelectronic, daim hlau nyias, thiab cov khoom siv hlau tsis zoo.

Tsis tas li ntawd, nws tuaj yeem raug cais ntxiv raws li kev sib txhuam mos (<450 ° C) thiab nyuaj brazing (> 450 ° C) nyob ntawm qhov kub ntawm cov khoom siv brazing yog rhuab.

Dual Beam Laser Vuam

Dual-beam vuam tso cai hloov tau yooj yim thiab yooj yim tswj ntawm laser irradiation lub sij hawm thiab txoj hauj lwm, yog li kho lub zog faib.

Nws yog tsuas yog siv rau laser vuam ntawm txhuas thiab magnesium alloys, splice thiab ceg tawv vuam rau tsheb, laser brazing thiab sib sib zog nqus fusion vuam.

Ob chav nqaj tuaj yeem tau txais los ntawm ob lub lasers ywj siab lossis los ntawm kev sib cais ntawm cov nqaj hlau.

Ob kab teeb tuaj yeem ua ke ntawm lasers nrog lub sijhawm sib txawv ntawm cov yam ntxwv (pulsed vs. nruam), sib txawv wavelengths (mid-infrared vs. pom wavelengths) thiab sib txawv powers, uas tuaj yeem xaiv raws li cov khoom siv ua tiav.

4.Laser Composite Vuam

Vim yog siv cov laser beam raws li lub tshav kub xwb, ib lub tshav kub qhov chaw laser welding muaj ib tug tsawg zog hloov dua siab tshiab tus nqi thiab siv tus nqi, lub weld puag cov ntaub ntawv chaw nres nkoj interface yog ib qho yooj yim los tsim misalignment, yooj yim los tsim pores thiab tawg thiab lwm yam shortcomings, txhawm rau daws qhov teeb meem no, koj tuaj yeem siv cov yam ntxwv ntawm cov cua sov ntawm lwm qhov chaw cua sov los txhim kho cov cua sov ntawm lub laser ntawm lub workpiece, feem ntau hu ua laser composite vuam.

Daim ntawv tseem ceeb ntawm laser composite welding yog qhov sib xyaw vuam ntawm laser thiab hluav taws xob arc, 1 + 1 > 2 nyhuv yog raws li nram no.

tom qab lub laser beam nyob ze ntawm daim ntawv thov arc,cov electron ceev yog ho txo, plasma huab generated los ntawm laser vuam yog diluted, uastuaj yeem ua rau lub laser nqus tau zoo heev, thaum lub arc ntawm lub hauv paus khoom preheating yuav ntxiv qhov nqus ntawm laser.

2. kev siv hluav taws xob siab ntawm arc thiab tag nrhokev siv hluav taws xob yuav nce ntxiv.

3, laser vuam cheeb tsam ntawm qhov kev txiav txim me me, yooj yim los ua misalignment ntawm vuam chaw nres nkoj, thaum lub thermal kev txiav txim ntawm lub arc loj, uas muaj peev xwmtxo qhov misalignment ntawm vuam chaw nres nkoj. Nyob rau tib lub sijhawm, lubvuam zoo thiab efficiency ntawm lub arc yog txhim khovim lub tsom thiab coj cov nyhuv ntawm lub laser beam ntawm lub arc.

4, laser vuam nrog lub siab ncov kub, loj tshav kub-cuam tshuam cheeb tsam, ceev ceev txias thiab solidification ceev, yooj yim los tsim cov kab nrib pleb thiab pores; thaum lub arc lub tshav kub cuam tshuam cheeb tsam me me, uas tuaj yeem txo qhov kub ntawm gradient, txias, solidification ceev,tuaj yeem txo thiab tshem tawm cov tiam ntawm pores thiab kab nrib pleb.

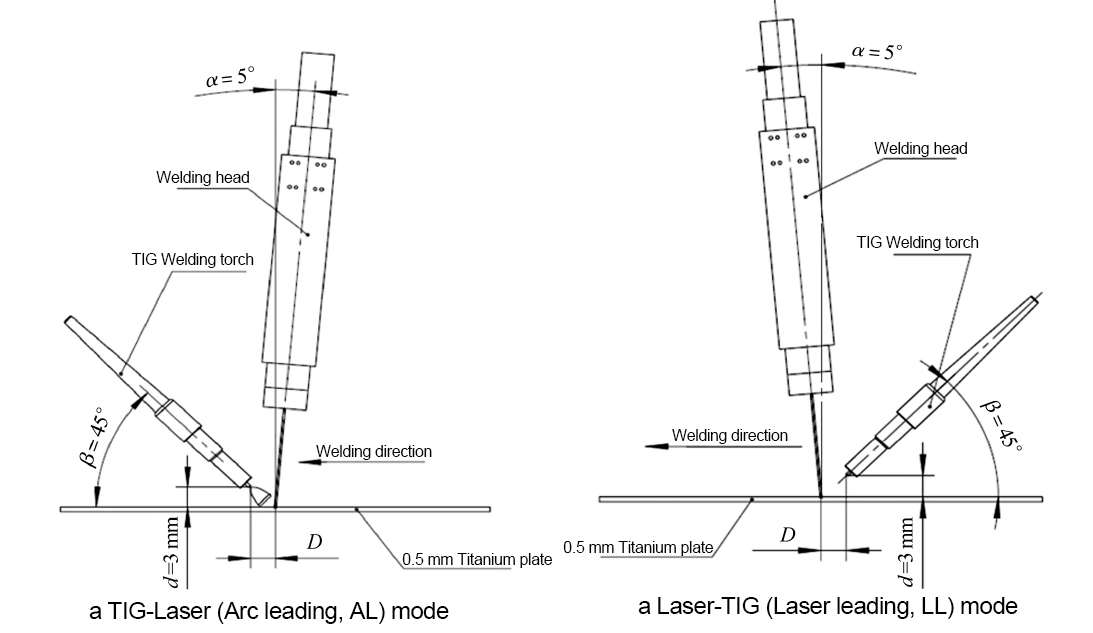

Muaj ob hom kev sib txuas ntawm laser-arc composite welding: laser-TIG puas vuam (raws li qhia hauv qab no) thiab laser-MIG sib txuas vuam.

Kuj tseem muaj lwm hom kev vuam xws li laser thiab plasma arc, laser thiab inductive heat source compound welding.

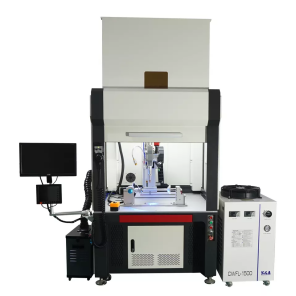

Hais txog MavenLaser

Maven Laser yog tus thawj coj ntawm laser industrialization daim ntawv thov nyob rau hauv Suav teb thiab cov chaw muab kev tso cai ntawm lub ntiaj teb no laser kev daws teeb meem. Peb nkag siab txoj kev loj hlob ntawm kev lag luam kev lag luam, niaj hnub txhawb peb cov khoom thiab cov kev daws teeb meem, hais kom tshawb nrhiav kev koom ua ke ntawm automation, kev qhia thiab kev txawj ntse nrog kev lag luam, muab cov khoom siv laser vuam, cov cuab yeej laser npav, cov khoom siv laser tu thiab laser kub thiab nyiaj hniav nyiaj hniav kub. txiav cov cuab yeej rau ntau yam kev lag luam nrog rau tag nrho lub zog series, thiab txuas ntxiv nthuav peb lub zog hauv kev lag luam ntawm cov khoom siv laser.

Post lub sij hawm: Jan-13-2023