1.Qhov zoo thiab qhov tsis zoo ntawm laser vuam tshuab thiab nws daim ntawv thov

Laser welding tshuab yog ib hom tshiab ntawm vuam txoj kev, nrog tsawg daim ntawv cog lus muaj zog, tshav kub-cuam tshuam cheeb tsam dav thiab ntau lwm yam zoo, nyob rau hauv lub tam sim no hlau ua lag luam, laser welding tau lug siv heev, tau ntev tau siv nyob rau hauv tag nrho cov mus rau lub neej. , xws li: hlau rwb thaiv tsev khob, xov tooj ntawm tes kev lag luam, kev kho mob kev lag luam, automotive kev lag luam thiab ntau lwm yam kev lag luam sectors.

01 Qhov zoo ntawm laser vuam tshuab

Piv nrog cov txheej txheem vuam tsoos, laser vuam tshuab tsis yog kev sib cuag vuam, cov txheej txheem kev ua haujlwm tsis tas yuav tsum muaj lub siab, muaj lub vuam ceev ceev, siab zog, qhov tob, me me deformation, nqaim weld seam, me me tshav kub-tshem tawm tsam, thiab lub workpiece. deformation yog me me, kev ua raws li cov txheej txheem ua haujlwm tsawg dua, txo cov ntaub ntawv tso tawm, kev ua haujlwm siab, kev nyab xeeb dua thiab lwm yam zoo.

Laser vuam tshuab siv tau los vuam cov ntaub ntawv refractory xws li high melting point hlau, thiab txawm tias cov ntaub ntawv uas tsis yog xim hlau xws li ceramics thiab organic iav, nrog zoo vuam tshwm sim ntawm cov ntaub ntawv zoo li tus thiab yooj yooj yim. Rau vuam tsis siv tau qhov chaw, hloov tau yooj yim kis tsis sib cuag welding yog ua. Lub laser beam tuaj yeem muab faib ua lub sijhawm thiab lub zog, ua rau kev ua haujlwm ib txhij ntawm ntau kab teeb, muab cov xwm txheej rau kev vuam ntau dua.

02 Cov ntsiab lus kom nco ntsoov ntawm kev siv cov tshuab laser vuam

Cov nram qab no yuav tsum raug sau tseg thaum siv cov khoom siv laser vuam tshuab

(a) Txoj hauj lwm ntawm cov welded ib feem yuav tsum tau meej heev, ua kom paub tseeb tias nws nyob rau hauv lub tsom xam ntawm lub laser beam.

(b) Thaum welded ib feem yuav tsum tau siv lub fixture, nws yuav tsum tau xyuas kom meej tias qhov kawg txoj hauj lwm ntawm lub welded ib feem yuav tsum tau ua raws li cov weld point qhov twg lub laser beam yuav cuam tshuam.

(c) Qhov siab tshaj plaws weldable thickness yog txwv, nkag mus rau workpieces nrog thicknesses zoo tshaj 19mm nyob rau hauv cov kab ntau lawm yuav tsum tau kev sab laj nrog cov chaw tsim tshuaj paus los muab kev pab cuam ntau tshaj.

03 Daim ntawv thov ntawm laser vuam tshuab

1. Roj teeb kev lag luam

Cov xov tooj ntawm tes thiab feem ntau ntawm cov khoom code ntawm lub roj teeb yog siv laser vuam.

2. chav dej chav ua noj kev lag luam

Laser vuam precision muaj ib tug zoo tsos, yog li nyob rau hauv cov qib high-qib chav dej stainless hlau khoom laser marking laser vuam muaj ntau yam kev siv. Xws li: tes tuav, faucets, stainless cutlery riam thiab feem ntau ntawm txoj kev nrog laser npav ntawm kev tsim cov tuam txhab LOGO, qib high-qib hluav taws xob kettles thiab lwm yam seals kuj siv laser welding kom tiav. Cov khoom siv hauv chav ua noj, cov khoom siv rooj tog zaum vuam taub qab vuam, qhib pwm pwm ua thiab kho thiab hloov pwm hauv cov txheej txheem siv.

3. Cov khoom lag luam digital, xov tooj ntawm tes, khoos phis tawj kev lag luam

Laser ua vim lub precision ua technology, nyob rau hauv lub digital, xov tooj ntawm tes, computer teb daim ntaub ntawv ntau nrov xws li: xov tooj ntawm tes, MP4, MP3 plhaub laser vuam, interface kab, laptop computers, fiber optic li chaw vuam, computer chassis connector welding. .

4. Engineering machinery kev lag luam

Purification khoom welding, electromechanical qhov chaw vuam, connector bearing kho.

5. Electronics, hluav taws xob kev lag luam

Txij li thaum laser ua yog ib txoj kev tsis sib cuag, nws tsis tsim mechanical extrusion lossis mechanical stress, yog li nws tshwj xeeb tshaj yog ua tau raws li qhov yuav tsum tau ua ntawm kev lag luam hluav taws xob. Xws li: transformers, inductors, connectors, terminals, fiber optic connectors, sensors, transformers, keyboards, cell phone batteries, microelectronic Cheebtsam, integrated circuit leads thiab lwm yam vuam.

6. Kev lag luam hniav nyiaj hniav kub

Txij li thaum laser ua tau zoo heev, nws yog qhov zoo tagnrho rau cov khoom muaj nqis thiab me me hauv kev lag luam hniav nyiaj hniav kub. Raws li lub laser tsom teeb pom kev zoo yog qhov zoo heev, nws tau nthuav dav los ntawm lub tshuab tsom iav kom nthuav dav qhov me me ntawm cov hniav nyiaj hniav kub thiab paub qhov tseeb vuam. Lub laser chaw welder yog ib qho khoom siv tsim nyog rau kev sib txuas ntawm cov hniav nyiaj hniav kub chains thiab inlay ntawm gemstones.

7. Kho vajtse, cuab yeej, instrumentation kev lag luam

Cov cuab yeej, sensor, chav ua noj, tableware pab pawg vuam taub qab vuam, qhib pwm pwm tsim thiab kho thiab hloov pwm thaum siv. Seamless vuam ntawm stainless hlau tableware, vuam ntawm kev sib txuas ntawm meter core.

8. Automotive, hluav taws xob tsheb kev lag luam

Laser ua rau kev ua tsis sib cuag, tsis muaj kuab paug rau cov khoom, kev kub ceev, zoo dua rau cov kev xav tau ntawm high-end automotive neeg siv khoom cov txheej txheem ntau lawm, xws li tsheb dial vuam, valve vuam, piston nplhaib vuam, automotive lub tog raj kheej gasket vuam, cov yeeb nkab, lim vuam, vuam ntawm automotive kev nyab xeeb roj generator. Laser txiav ntawm qhov chaw nyob rau hauv kev sim thiab me me batch ntau lawm theem ntawm tsheb, thiab vuam ntawm cov roj teeb rau hluav taws xob tsheb.

9. Lub zog teeb pom kev lag luam khoom siv

Laser ua yog dav siv nyob rau hauv laser solar cell manufacturing: xws li hnub ci silicon wafer laser scribing txiav, hnub ci dej rhaub kub conduction phaj vuam. Laser ua, raws li ib puag ncig tus phooj ywg thiab kev ua haujlwm zoo, yuav siv dav dua yav tom ntej.

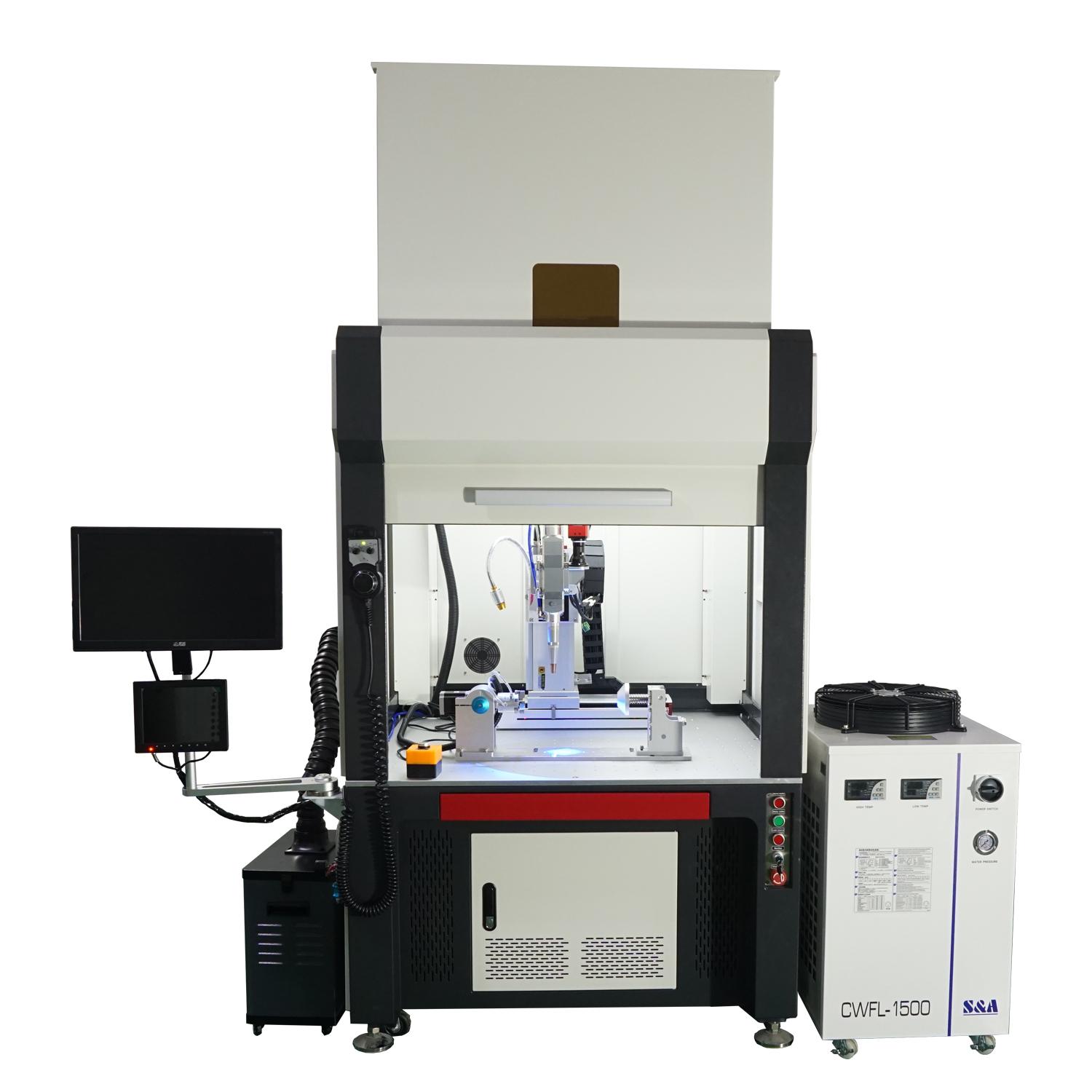

2.Dab tsi yog Platform tsis siv neeg laser vuam tshuab?

Platform tsis siv neeg laser vuam tshuab yog lub tshuab vuam tsis siv neeg uas siv lub zog laser pulses rau hauv zos kom sov cov khoom hauv ib cheeb tsam me me. Lub zog ntawm lub laser hluav taws xob yog diffused los ntawm tshav kub conduction mus rau sab hauv ntawm cov khoom thiab cov khoom yog melted los ua ib tug tshwj xeeb molten pas dej ua ke. Nws yog tsuas yog siv rau vuam ntawm nyias-walled cov ntaub ntawv thiab precision qhov chaw, thiab muaj peev xwm paub qhov hluav taws xob vuam, taub qab vuam, ncej puab vuam, foob vuam, thiab lwm yam. porosity, tswj kom raug, siab qhov chaw raug, thiab yooj yim automation.

3.Dab tsi yog handheld laser vuam tshuab?

Raws li lub npe implies, phau ntawv laser vuam tshuab yog ib hom vuam cov cuab yeej uas yuav tsum tau ua haujlwm. Cov cuab yeej siv vuam no tuaj yeem ua laser vuam ntawm cov haujlwm ntev thiab loj. Thaum vuam, lub tshav kub cuam tshuam qhov chaw me me thiab tsis ua rau deformation, blackening thiab cov cim nyob rau sab nraum qab ntawm lub workpiece. Qhov vuam qhov tob yog qhov loj, qhov vuam yog ruaj khov, lub melting yog txaus, thiab tsis muaj kev nyuaj siab nyob rau hauv lub melt pas dej ua ke qhov projection ntawm cov khoom molten raws li lub substrate.

4.Dab tsi yog qhov txawv ntawm tsis siv neeg laser vuam tshuab thiab handheld laser vuam tshuab?

Tsis siv neeg laser vuam tshuab txiav vuam raws li qhov kev pab cuam tom qab tau teeb tsa hauv software; phau ntawv laser vuam tshuab, tseem hu ua qhov chaw vuam, yog siv los ntawm cov neeg siv thaum siv cov khoom siv laser vuam los ntawm kev nthuav dav rau qhov screen.

Kev pom qhov chaw vuam yog ua manually thiab feem ntau yog kev cai tsim los ntawm cov cuab yeej laser manufacturers kom tau raws li cov neeg siv khoom xav tau. Qee lub tuam txhab muaj cov khoom lag luam. Yog tias cov khoom lag luam muaj, lawv tau muab rau tus neeg siv raws li tus qauv lossis cov ntaub ntawv pov thawj. Qhov tseem ceeb tshaj plaws, lub zog thiab cov yam ntxwv ntawm cov khoom siv vuam yog txiav txim siab los ntawm kev sib tham nrog tus neeg siv, thiab peb kuj yuav tsum muab cov neeg siv khoom siv cov khoom siv zoo raws li tus nqi ntawm kev yuav khoom. Nyob rau hauv dab tsi nws yog zoo dua los siv ib tug phau ntawv laser welding tshuab, piv rau ib tug tag nrho automated laser vuam tshuab, tsis tsuas yog tus nqi yuav khoom siab, tab sis tus nqi kho mob kuj siab heev. Qhov ntau yog ib yam dab tsi yog qhov tseem ceeb dua rau kev tu thiab ib txwm muaj tus nqi siab dua. Tsis tas li ntawd, tag nrho tsis siv neeg laser vuam feem ntau yog tsom rau ntawm CNC automation ntawm kev ua haujlwm platform, uas yuav tsum muaj kev ua haujlwm siab thiab ntau yam ntawm kev ua haujlwm platform, tab sis hauv kev xyaum, qhov no tsis yog panacea, thiab ntau yam khoom siv sib txawv tsis tuaj yeem siv, uas. txwv lub luag haujlwm ntawm tsis siv neeg laser vuam tshuab. Niaj hnub no, peb tsom mus rau phau ntawv laser vuam tshuab, yog li phau ntawv ntaus ntawv ib txwm daws cov teeb meem saum toj no. Nws txoj haujlwm vuam yog ua haujlwm vuam los ntawm kev tuav lub laser vuam sib koom ua ke nrog ntau lub kaum ntse ntse, yog li nws tuaj yeem hais tias yog cov khoom siv laser tsis raug cai kom hloov mus rau vuam ntawm ntau cov duab thiab cov kaum ntawm cov khoom. Ntev npaum li lub hwj chim siab txaus, nws tuaj yeem hloov mus rau qhov vuam ntawm cov khoom siv feem ntau

Cov khoom tsim tau ntawm phau ntawv laser vuam tshuab yog qhov tsawg dua li ntawm cov cuab yeej siv tshuab tag nrho. Txawm li cas los xij, rau kev ua haujlwm tsis zoo lossis tsis ua haujlwm loj thiab vuam ntawm cov nroj tsuag ntau lawm, phau ntawv laser vuam yog qhov zoo dua. Tsis tas yuav teeb tsa lub rooj vuam thiab zam qhov teeb meem ntawm qhov chaw loj hauv pem teb. Tsis tas li ntawd, kev cob qhia me me welding ntau yam khoom nrog cov duab tsis sib xws, yog li phau ntawv laser vuam tuaj yeem ua tau raws li qhov xav tau ntawm cov khoom siv no thiab muaj qhov hloov tau zoo.

Los ntawm txhais tes laser welding tsis precision vuam rooj, tsawg noj consumables thiab tsis tshua muaj txij nkawm tus nqi ntawm cov khoom. Feem ntau hais lus, peb yuav tsum tswj hwm ntau qhov chaw ua haujlwm, thaum cov cuab yeej siv laser tuaj yeem ua tiav cov haujlwm ntev npaum li nws tau nruab nrog cov khoom siv hluav taws xob laser vuam. Ib qho yooj yim los hloov, tus nqi qis ntawm cov khoom hloov pauv. Yog tias koj tsis paub yuav hloov lawv li cas, koj tuaj yeem muab lawv rau cov chaw tsim khoom rau kev saib xyuas ncaj qha yam tsis muaj kev txhawj xeeb txog kev xa khoom.

Qhov sib txawv ntawm tsis siv neeg laser vuam tshuab thiab phau ntawv laser vuam tshuab tau qhia ntawm no. Ntau tus neeg yuav xav tias tsis siv neeg laser welder yog qhov zoo dua vim nws tsis siv neeg, tab sis qhov tseeb yog tias ob hom khoom siv rau ntau lub hom phiaj thiab txhua tus muaj nws tus kheej zoo. Hauv cov txheej txheem xaiv, peb kuj yuav tsum xaiv cov khoom siv laser vuam zoo rau peb cov khoom raws li peb cov kev xav tau tiag tiag.

Post lub sij hawm: Feb-01-2023