Vim li cas xaivQCW pwm kho fiber optic vuam mach

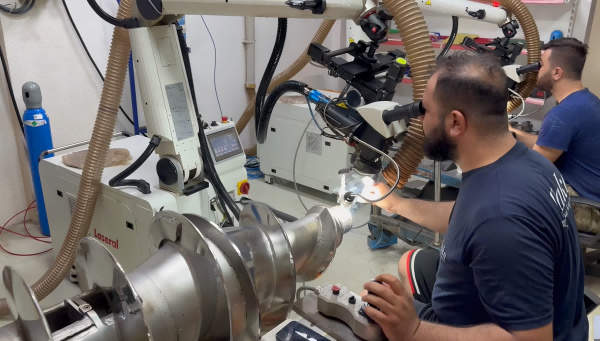

Kev kho pwm yog txheej txheem tseem ceeb hauv kev tsim khoom, thiab muaj cov cuab yeej thiab cov cuab yeej zoo yog qhov tseem ceeb rau kev ua tiav cov txiaj ntsig zoo. Ib qho cuab yeej zoo li no tau nrov nyob rau xyoo tas los no yog QCW pwm khofiber ntau welder. Lub tshuab tshiab no hloov pauv cov txheej txheem kho pwm, muab ntau yam txiaj ntsig thiab cov yam ntxwv uas ua rau nws xaiv thawj zaug rau cov tuam ntxhab thiab cov kws kho pwm. Hauv tsab xov xwm no, peb yuav tshawb xyuas cov yam ntxwv ntawm pwm vuam tshuab thiab delve rau hauv dab tsi ua rau QCW Pwm Kho Fiber Vuam Tshuab sawv tawm.

Pwm vuam tshuabyog tsim los kho thiab kho cov pwm siv hauv ntau cov txheej txheem tsim khoom. Cov tshuab no siv cov thev naus laus zis thev naus laus zis los kho cov kab nrib pleb, chips thiab lwm yam kev puas tsuaj rau pwm, kom ntseeg tau tias lawv tuaj yeem tsim cov khoom zoo. Thaum xaiv lub tshuab pwm welding, muaj ob peb yam tseem ceeb los xav txog. Cov no suav nrog precision, efficiency, versatility thiab yooj yim ntawm kev siv.

QCW Pwm Kho Fiber Vuam Tshuab ua tau zoo nyob rau hauv tag nrho cov cheeb tsam no, ua rau nws xaiv zoo tshaj plaws rau cov kws kho pwm. Cia peb ua tib zoo saib cov yam ntxwv uas teeb tsa lub tshuab no sib nrug ntawm kev sib tw.

Precision yog qhov tseem ceeb hauv kev kho pwm vim tias txawm tias qhov tsis xws luag tuaj yeem cuam tshuam qhov zoo ntawm qhov ua tiav. Lub QCW pwm kho fiber ntau optic vuam tshuab yog nruab nrog cov tshuab laser qib siab rau qhov tseeb thiab raug vuam. Qib no ua kom ntseeg tau tias cov pwm kho tau tswj hwm nws qhov loj me thiab cov lus qhia tshwj xeeb, tsim cov khoom ua tau raws li cov qauv zoo tshaj plaws.

Kev ua tau zoo yog lwm qhov tseem ceeb ntawm cov pwm vuam tshuab. QCW pwm kho fiber optic vuam tshuab nta ceev vuam ceev, ua kom kho sai thiab txo qis qis qis thaum tsim khoom. Qhov kev ua tau zoo no yog qhov tseem ceeb rau kev tswj cov khoom tsim tau thiab ua tau raws li lub sijhawm tsim khoom, ua QCW cov tshuab ua khoom muaj txiaj ntsig rau cov tuam txhab.

Versatility kuj yog ib qho tseem ceeb rau kev txiav txim siab thaum xaiv lub tshuab pwm vuam. QCW pwm kho fiber ntau welder muaj peev xwm kho ntau yam khoom pwm, suav nrog hlau, txhuas thiab ntau yam alloys. Qhov no versatility ua rau nws haum rau ntau yam kev tsim daim ntaub ntawv, muab yooj yooj yim rau pwm kho cov tub txawg.

Kev yooj yim ntawm kev siv yog qhov tseem ceeb ntawm txhua yam khoom siv, thiab QCW Pwm Kho Fiber Vuam Tshuab yog tsim los nrog cov neeg siv khoom zoo uas tso cai rau cov neeg ua haujlwm ntawm ntau qib kev txawj siv nws. Intuitive tswj, ergonomic tsim thiab kev cob qhia thiab kev txhawb nqa kom cov neeg siv tuaj yeem paub lub tshuab sai thiab ua tiav cov txiaj ntsig zoo

Ntxiv rau cov yam ntxwv no, muaj ntau qhov laj thawj tshwj xeeb vim li cas QCW Pwm Kho Fiber Welder yog thawj qhov kev xaiv ntawm cov kws kho pwm. Ib qho ntawm cov txiaj ntsig tseem ceeb ntawm lub tshuab no yog lub peev xwm los kho qhov tsis tas yuav tsum tau ua kom dav dav preheating lossis kev kho cua sov tom qab vuam. Qhov no tsis tsuas yog txuag lub sijhawm, nws tseem txo qhov kev pheej hmoo ntawm thermal deformation thiab tswj kev ncaj ncees ntawm pwm.

Tsis tas li ntawd, QCW pwm kho fiber ntau vuam tshuab nta zoo vuam lub zog thiab zoo, kom ntseeg tau tias kho pwm tuaj yeem tiv taus qhov kev siv tsis tu ncua thaum lub sijhawm tsim khoom. Qhov kev ua haujlwm ntev no yog qhov tseem ceeb rau kev ua kom lub neej ntawm pwm thiab txo qhov zaus ntawm kev kho, thaum kawg txuag lub sijhawm thiab nyiaj txiag rau cov tuam txhab.

Lwm qhov laj thawj tseem ceeb los xaiv QCW pwm kho fiber ntau welder yog nws lub peev xwm ua tiav seamless welds nrog cov khoom siv tsawg heev. Qhov no ua rau muaj kev huv, meej tiav yam tsis tas yuav tsum tau siv dav tom qab vuam thiab polishing. QCW cov cav tov muaj peev xwm ua tau zoo welds nrog tsawg cov khoom distortion, uas teev QCW cov cav tov sib nrug los ntawm ib txwm welding txoj kev.

Tsis tas li ntawd, QCW pwm kho fiber ntau vuam tshuab yog nruab nrog kev saib xyuas thiab kev tswj xyuas kom ntseeg tau tias vuam zoo thiab txo qhov kev pheej hmoo ntawm qhov tsis xws luag. Qib no ntawm automation thiab precision txo qhov kev cia siab ntawm tus neeg teb xov tooj kev txawj thiab kev paub dhau los, ua rau lub tshuab nkag mus rau ntau yam ntawm cov neeg siv.

Hauv cov ntsiab lus, QCW Pwm Kho Fiber Vuam Tshuab ua ke nrog precision, efficiency, versatility thiab yooj yim ntawm kev siv, ua rau nws yog thawj xaiv rau pwm kho cov tub txawg. Nws muaj peev xwm muab cov welds zoo, tsawg thermal distortion, superior zog thiab seamless tiav ua rau nws yog ib qho zoo heev rau kev kho pwm. Nrog QCW cov cav tov, cov tuam txhab lag luam tuaj yeem ua tiav kev kho kom ruaj khov thiab kav ntev, thaum kawg pab ua kom muaj txiaj ntsig thiab txuag nqi. Thaum nws los txog rau kev kho pwm, xaiv cov cuab yeej zoo yog qhov tseem ceeb, thiab QCW Pwm Kho Fiber Vuam Tshuab yog undoubtedly qhov kev xaiv hauv kev lag luam.

Post lub sij hawm: Sep-06-2024

.png)

.png)

.png)