Raws li tus neeg nqa khoom ntawm lwm qhov ntawm lub tsheb, kev tsim tshuab ntawm lub cev lub tsheb ncaj qha txiav txim siab tag nrho kev tsim khoom zoo ntawm lub tsheb.Nyob rau hauv tus txheej txheem ntawm nws pib lub cev manufacturing, vuam yog ib qho tseem ceeb txheej txheem ntau lawm.Lub vuam thev naus laus zis tam sim no siv rau nws lub cev vuam feem ntau suav nrog qhov chaw vuam, molten inert gas shielded vuam (MIG welding) thiab molten active gas shielded arc vuam (MAG welding) nrog rau laser vuam.

Raws li kev siv thev naus laus zis thev naus laus zis nrog kev sib koom ua ke kho qhov muag-mechanical, laser vuam tshuab muaj qhov zoo ntawm lub zog siab ceev, vuam ceev ceev, vuam tsis tshua muaj kev ntxhov siab thiab deformation, thiab kev ua haujlwm zoo piv nrog cov tsoos pib lub cev vuam tshuab.

Lub tsheb lub cev qauv yog complex, thiab lub cev qhov chaw yog feem ntau nyias-walled thiab nkhaus Cheebtsam.Nws pib lub cev vuam yog ntsib nrog cov teeb meem vuam xws li kev hloov pauv ntawm cov khoom siv hauv lub cev, qhov sib txawv ntawm lub cev qhov chaw, ntau hom vuam trajectories thiab cov ntaub ntawv sib koom ua ke.Tsis tas li ntawd, automotive lub cev vuam muaj qhov yuav tsum tau ua ntawm vuam zoo thiab vuam efficiency.

Raws li cov txheej txheem vuam tsim nyog, laser vuam tuaj yeem ua kom muaj zog qaug zog thiab cuam tshuam rau lub cev qhov tseem ceeb ntawm lub cev thaum vuam, yog li ua kom ntseeg tau qhov zoo thiab kev pabcuam lub neej ntawm lub cev vuam.Laser vuam tshuab tuaj yeem hloov kho rau vuam ntawm nws pib lub cev qhov chaw nrog cov ntaub ntawv sib koom ua ke, cov thicknesses sib txawv thiab cov khoom sib txawv, ua tau raws li qhov xav tau ntawm kev hloov pauv hauv nws lub cev tsim.Yog li ntawd, laser vuam tshuab yog ib qho tseem ceeb kev txhais tau tias kom ua tiav kev loj hlob zoo ntawm kev lag luam tsheb.

Laser vuam txheej txheem rau automotive lub cev

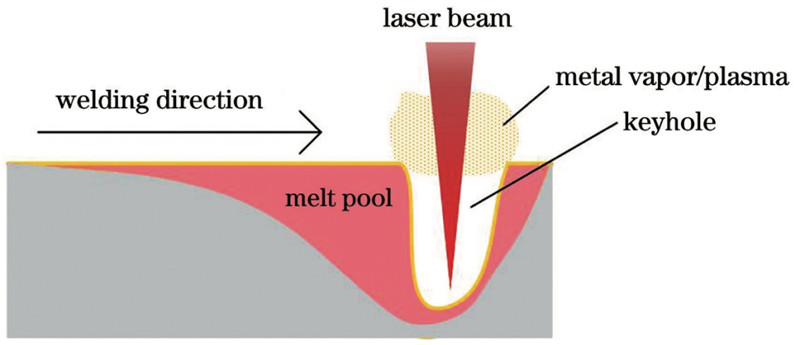

Laser sib sib zog nqus fusion vuam txheej txheem txoj cai: Thaum lub laser zog ceev mus txog ib theem, cov khoom nto vaporizes, yog li tsim ib tug keyhole.Thaum cov hlau vapor siab nyob rau hauv lub qhov mus txog dynamic equilibrium nrog lub siab zoo li qub thiab nto nro ntawm cov kua ib puag ncig, lub laser tuaj yeem irradiate los ntawm lub qhov tseem ceeb mus rau hauv qab ntawm lub qhov, thiab nrog lub zog ntawm lub laser beam, ib tug nruam weld. tsim.Nyob rau hauv lub laser sib sib zog nqus fusion vuam txheej txheem, tsis tas yuav ntxiv auxiliary flux los yog muab tub lim rau welding lub workpiece tus kheej cov khoom rau hauv ib tug.

Lub weld seam tau los ntawm laser sib sib zog nqus fusion vuam feem ntau yog du thiab ncaj nrog me me deformation, uas yog qhov tsim nyog rau kev txhim kho cov khoom raug ntawm nws lub cev.Lub zog tensile ntawm lub vuam yog siab, uas ua kom lub vuam zoo ntawm lub cev pib.Qhov vuam ceev yog ceev, uas yog qhov zoo rau kev txhim kho vuam ntau lawm efficiency.

Nyob rau hauv nws pib lub cev vuam txheej txheem, kev siv laser sib sib zog nqus fusion vuam txheej txheem yuav txo tau tus naj npawb ntawm qhov chaw, pwm thiab vuam cuab yeej, yog li txo qhov hnyav tuag ntawm lub cev thiab cov nqi ntau lawm.Txawm li cas los xij, cov txheej txheem sib sib zog nqus laser sib sib zog nqus tsis tshua muaj siab ntev rau qhov sib dhos ntawm cov khoom yuav tsum tau welded, thiab qhov sib dhos sib dhos yuav tsum tau tswj ntawm 0.05 thiab 2 hli.Yog hais tias qhov sib dhos qhov sib txawv loj heev, vuam tsis xws li porosity yuav tshwm sim.

Kev tshawb fawb tam sim no qhia tau hais tias nyob rau hauv nws pib lub cev vuam ntawm tib cov khoom, los ntawm optimizing cov txheej txheem tsis laser sib sib zog nqus fusion vuam, nws muaj peev xwm kom tau ib tug weld nrog zoo nto tsim, tsawg dua sab hauv tsis xws luag thiab zoo heev mechanical zog.Cov khoom zoo heev ntawm cov khoom siv vuam tuaj yeem ua tau raws li kev siv cov khoom siv ntawm lub cev welded.Txawm li cas los xij, nyob rau hauv nws pib lub cev vuam, aluminium alloy-steel raws li tus neeg sawv cev ntawm heterogeneous hlau laser sib sib zog nqus fusion vuam txheej txheem tsis paub tab, txawm hais tias los ntawm kev ntxiv cov txheej txheem kev hloov pauv tuaj yeem tau txais kev ua tau zoo ntawm cov vuam, tab sis cov ntaub ntawv sib txawv ntawm cov txheej txheem sib txawv ntawm qhov sib txawv ntawm cov khoom siv vuam. IMC txheej cuam tshuam mechanism thiab nws cov nyhuv ntawm micro qauv ntawm weld mechanism tsis meej, xav tau kev kawm ntxiv rau qhov tob.

Nws pib lub cev Laser Hlau Filling Vuam txheej txheem

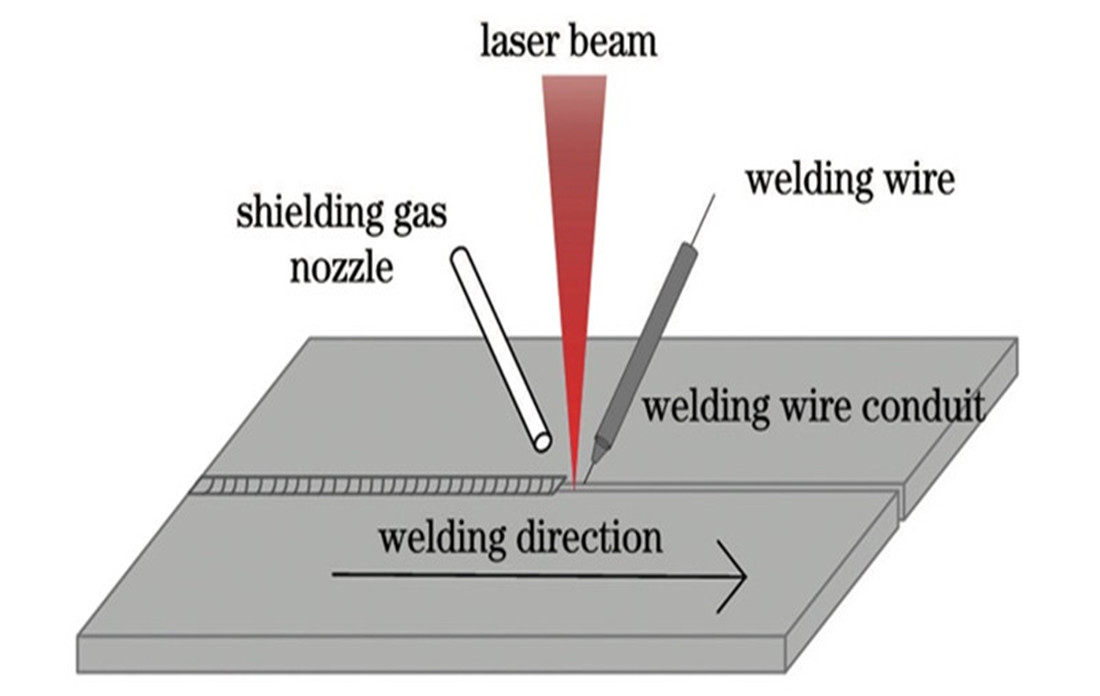

Lub laser muab tub lim welding txheej txheem yog raws li hauv qab no: Ib tug welded sib koom ua ke yog tsim los ntawm pre-filling lub weld nrog ib tug tshwj xeeb hlau los yog los ntawm pub cov hlau ib txhij thaum lub sij hawm lub laser vuam txheej txheem.Qhov no yog sib npaug rau kev pub noj ib yam li homogeneous ntawm cov khoom siv hlau rau hauv lub pas dej ua ke thaum lub sij hawm laser sib sib zog nqus fusion vuam.Daim duab hauv qab no qhia txog cov txheej txheem laser muab tub lim.

Piv nrog rau laser sib sib zog nqus fusion vuam, laser muab tub lim vuam muaj ob qhov zoo hauv nws lub cev vuam: ua ntej, nws tuaj yeem txhim kho qhov kev ua siab ntev ntawm kev sib dhos ntawm nws lub cev qhov chaw yuav tsum tau welded thiab daws qhov teeb meem ntawm siab bevel sib txawv yuav tsum tau rau laser sib sib zog nqus vuam vuam. ;Thib ob, nws tuaj yeem txhim kho cov ntaub so ntswg hauv thaj chaw weld los ntawm kev siv cov xov hlau nrog cov ntsiab lus sib txawv, thiab tom qab ntawd tswj cov kev ua haujlwm ntawm vuam.

Nyob rau hauv tus txheej txheem ntawm nws pib lub cev manufacturing, laser muab tub lim vuam txheej txheem yog tsuas yog siv rau weld aluminium alloy thiab steel qhov chaw ntawm lub cev.Tshwj xeeb tshaj yog nyob rau hauv cov txheej txheem vuam ntawm aluminium alloy qhov chaw ntawm nws pib lub cev, qhov nro ntawm lub pas dej molten yog me me, uas tuaj yeem yooj yim ua rau lub cev qhuav dej ntawm lub pas dej molten, thaum lub laser muab tub lim vuam txheej txheem tuaj yeem daws qhov teeb meem ntawm lub pas dej molten. los ntawm melting ntawm cov hlau nyob rau hauv lub laser vuam txheej txheem.

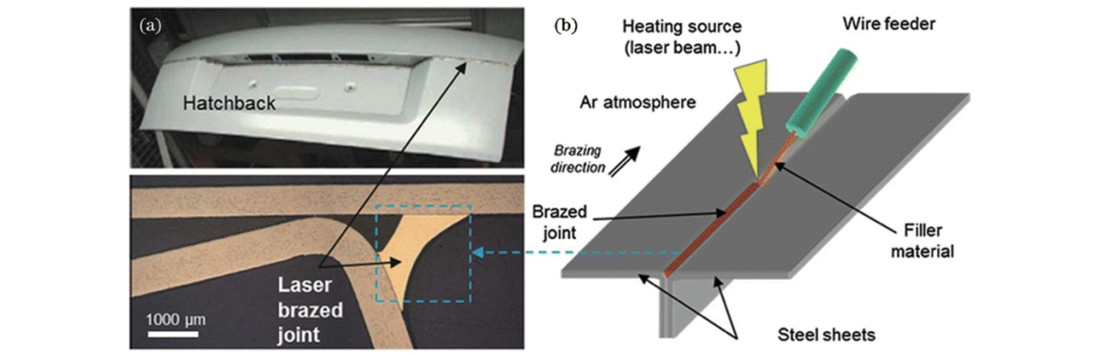

Automotive lub cev laser brazing txheej txheem

Cov txheej txheem laser brazing yog raws li hauv qab no: Siv lub laser los ua qhov cua sov, lub teeb laser yog tsom thiab irradiated mus rau saum npoo ntawm cov hlau, cov hlau melts, cov hlau melted drips thiab puv lub workpiece yuav tsum tau welded, thiab metallurgical teebmeem xws li melting thiab diffusion tshwm sim ntawm cov khoom siv brazing thiab cov khoom ua haujlwm, yog li koom nrog cov khoom ua haujlwm.Tsis zoo li cov txheej txheem laser muab tub lim, cov txheej txheem laser brazing tsuas yog melts cov hlau thiab tsis yog lub workpiece yuav tsum tau welded.Laser brazing muaj qhov zoo welding stability, tab sis lub zog tensile ntawm qhov tshwm sim weld yog tsawg.Daim duab 3 qhia txog daim ntawv thov ntawm laser brazing txheej txheem nyob rau hauv automotive nra compartment cover welding

Nyob rau hauv tus txheej txheem ntawm nws pib lub cev welding, laser brazing txheej txheem yog tsuas yog siv los welding lub cev qhov chaw uas tsis yuav tsum tau muaj zog sib koom ua ke, xws li cov vuam ntawm lub sab saum toj cover thiab sab ib puag ncig, lub vuam ntawm lub sab sauv thiab qis ib feem ntawm lub nra. compartment cover, thiab lwm yam. Lub hau sab saum toj ntawm VW, Audi thiab lwm yam nruab nrab thiab high-end qauv yog tag nrho cov siv laser brazing txheej txheem.

Lub ntsiab tsis xws luag nyob rau hauv laser brazed pob qij txha ntawm lub tsheb lub cev muaj xws li ntug gnawing, porosity, weld deformation, thiab lwm yam., thiab cov tsis xws luag yuav tsum ho suppressed los ntawm regulating cov txheej txheem tsis thiab siv multi-focus laser brazing txheej txheem.

Automotive lub cev laser-arc composite vuam txheej txheem

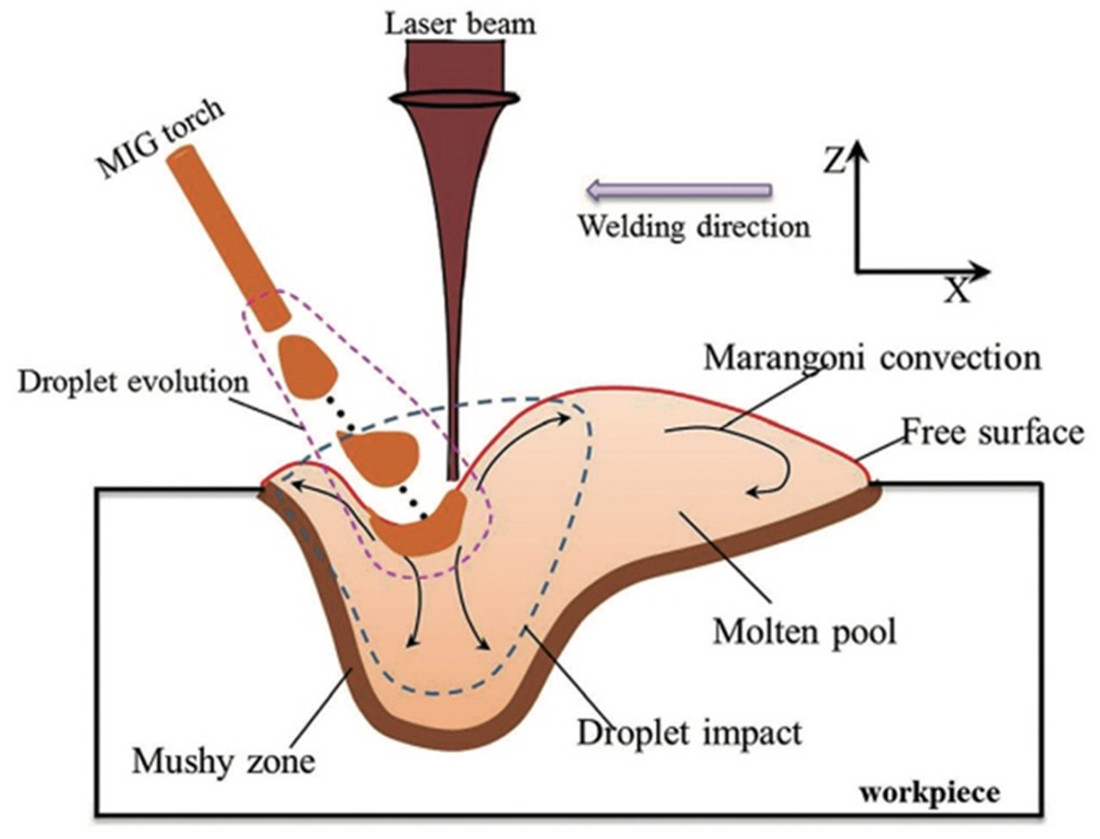

Lub hauv paus ntsiab lus ntawm laser-arc composite welding txheej txheem yog raws li nram no: ob lub tshav kub qhov chaw, laser thiab arc, yog siv nyob rau tib lub sij hawm ua rau ntawm qhov chaw ntawm lub workpiece yuav tsum tau welded, thiab lub workpiece yog melted thiab solidified los tsim ib tug weld seam.Daim duab hauv qab no qhia txog cov txheej txheem laser-arc vuam.

Laser-arc composite vuam sib txuas ua ke qhov zoo ntawm laser vuam thiab arc vuam: ua ntej, nyob rau hauv qhov kev txiav txim ntawm dual tshav kub qhov chaw, vuam ceev yuav nce, lub tshav kub input yuav me me, lub vuam deformation yog me me, tswj cov yam ntxwv ntawm laser vuam. ;thib ob, zoo dua bridging muaj peev xwm, sib dhos sib txawv kam rau ua yog ntau dua;thib peb, lub solidification ceev ntawm lub molten pas dej ua ke ua qeeb qeeb, uas yog conducive mus rau tshem tawm ntawm pores, tawg thiab lwm yam vuam tsis xws luag, txhim kho lub koom haum thiab kev ua tau zoo ntawm tshav kub-tshem tawm tsam plaub, vim lub arc, nws muaj peev xwm welding. cov ntaub ntawv nrog siab reflectivity thiab siab thermal conductivity, nrog rau ntau yam ntawm cov ntaub ntawv siv.

Nyob rau hauv nws pib lub cev raug txheej txheem, laser - arc puas welding txheej txheem yog tsuas yog welding lub cev aluminium alloy Cheebtsam thiab txhuas alloy - steel dissimilar hlau, rau lub sib dhos sib txawv ntawm qhov loj ntawm lub vuam, xws li lub tsheb qhov rooj ib feem ntawm qhov chaw. qhov vuam, qhov no yog vim qhov sib dhos sib txawv yog qhov zoo rau lub laser - arc puas vuam bridging kev ua tau zoo.Tsis tas li ntawd, lub laser-MIG arc composite vuam tshuab kuj tseem siv rau sab ru tsev beam txoj hauj lwm ntawm Audi lub cev.

Nyob rau hauv nws pib lub cev vuam txheej txheem, laser-arc composite welding muaj qhov zoo ntawm qhov sib txawv loj kam rau ua piv rau ib leeg laser vuam, txawm li cas los xij, laser-arc puas vuam yuav tsum muaj kev xav txog qhov txheeb ze ntawm lub laser thiab arc, laser vuam tsis, arc. parameters thiab lwm yam.Lub tshav kub thiab huab hwm coj hloov pauv ntawm cov txheej txheem laser-arc vuam yog qhov nyuaj, tshwj xeeb tshaj yog cov kev tswj hwm lub zog ntawm cov khoom siv vuam sib txuas thiab cov txheej txheem ntawm IMC thickness thiab cov ntaub so ntswg kev cai tseem tsis tau meej thiab yuav tsum tau ntxiv dag zog rau kev tshawb fawb.

Lwm yam automotive lub cev laser vuam txheej txheem

Laser sib sib zog nqus fusion vuam, laser muab tub lim vuam, laser brazing thiab laser-arc composite vuam thiab lwm yam vuam txheej txheem muaj ib tug paub tab ntau txoj kev xav thiab ntau yam ntawm cov tswv yim siv.Raws li kev lag luam tsheb cov kev xav tau rau lub cev vuam efficiency nce thiab qhov kev thov rau vuam ntawm cov khoom sib txawv hauv kev tsim khoom hnyav nce, laser chaw vuam, laser oscillation vuam, ntau laser nqaj vuam thiab laser davhlau vuam tau txais kev mloog.

Laser qhov chaw vuam txheej txheem

Laser qhov chaw welding yog ib qho kev siv tshuab laser welding zoo heev nrog qhov zoo ntawm kev vuam ceev ceev thiab siab vuam raug.Lub hauv paus ntsiab lus ntawm laser chaw welding yog tsom lub laser beam ntawm qhov taw tes ntawm qhov yuav tsum tau welded, kom cov hlau ntawm qhov taw tes ntawd melts instantly, thiab los ntawm kev kho cov laser ceev kom ua tiav thermal conduction vuam los yog sib sib zog nqus fusion vuam nyhuv, Thaum lub laser beam tsis ua hauj lwm, cov kua hlau refluxes, solidifies thiab ua ib qho kev sib koom ua ke.

Muaj ob yam tseem ceeb ntawm laser chaw vuam: pulsed laser chaw vuam thiab nruam laser chaw vuam.Lub laser beam nyob rau hauv pulsed laser chaw vuam muaj lub siab ncov lub zog, tab sis lub sij hawm ua hauj lwm luv luv, thiab feem ntau yog siv rau vuam ntawm lub teeb hlau xws li magnesium alloys thiab txhuas alloys.Nyob rau hauv tas li ntawd mus laser chaw vuam, lub laser beam muaj ib tug siab nruab nrab lub zog thiab lub sij hawm ntev laser txiav, thiab feem ntau yog siv rau vuam ntawm hlau.

Nyob rau hauv nws pib lub cev vuam, piv nrog rau qhov chaw vuam, laser chaw vuam muaj qhov zoo ntawm qhov tsis sib cuag thiab nws tus kheej tsim qhov chaw vuam trajectory, uas tuaj yeem ua tau raws li qhov kev thov rau cov vuam zoo hauv qab sib txawv ntawm qhov sib txawv ntawm nws lub cev cov ntaub ntawv.

Laser oscillation vuam txheej txheem

Laser oscillation welding yog ib qho tshiab laser vuam tshuab uas tau thov nyob rau hauv xyoo tas los no thiab tau txais kev saib xyuas dav.Lub hauv paus ntsiab lus ntawm cov thev naus laus zis no yog kom ua tiav qhov nrawm, kev txiav txim siab thiab me me oscillation ntawm lub laser beam los ntawm kev sib koom ua ke ib daim iav oscillating rau hauv lub laser vuam taub hau, yog li ua tiav cov nyhuv ntawm nplawm lub nqaj thaum mus tom ntej thaum lub sij hawm laser vuam.

Lub ntsiab oscillation trajectories nyob rau hauv lub laser oscillation vuam txheej txheem muaj xws li: transverse oscillation, longitudinal oscillation, ncig oscillation thiab infinite oscillation.Cov txheej txheem laser oscillation vuam muaj qhov zoo tseem ceeb hauv nws lub cev vuam, vim tias lub xeev ntws ntawm lub pas dej yaj tau hloov pauv los ntawm kev oscillation ntawm lub laser beam, yog li cov txheej txheem tuaj yeem tshem tawm qhov tsis xws luag, ua tiav cov khoom ua kom zoo dua qub thiab txo cov porosity hauv vuam ntawm tib yam khoom siv lub cev, thiab txhim kho cov teeb meem ntawm kev sib xyaw tsis txaus ntawm cov khoom sib txawv thiab cov khoom siv tsis zoo ntawm cov vuam seam hauv vuam ntawm cov khoom siv lub cev tsis sib xws.

Multi-laser beam vuam txheej txheem

Tam sim no, fiber ntau lasers tuaj yeem siv los faib ib lub laser beam rau ntau lub laser kab siv siv lub beam splitting module ntsia rau hauv lub taub hau vuam.Multi-laser beam welding yog sib npaug rau kev siv ntau qhov chaw tshav kub hauv cov txheej txheem vuam.Los ntawm kev kho lub zog faib ntawm cov nqaj sib txawv tuaj yeem ua tiav lub zog sib txawv yog lub nqaj tseem ceeb dua, lub luag haujlwm rau kev sib zog nqus vuam;lub sub-beam nrog qis zog ceev tuaj yeem ntxuav thiab preheat cov khoom nto thiab ua rau kom lub zog nqus ntawm laser beam los ntawm cov khoom.

Cov txheej txheem ntau lub laser beam welding tuaj yeem txhim kho tus cwj pwm evaporation ntawm zinc vapor thiab tus cwj pwm dynamic ntawm lub pas dej ua ke thaum lub sij hawm vuam ntawm galvanized steel los xij, txhim kho qhov teeb meem spattering thiab txhim kho lub zog tensile ntawm vuam seam.

Laser davhlau vuam txheej txheem

Laser davhlau vuam tshuab yog ib tug tshiab laser vuam tshuab nrog siab vuam efficiency thiab autonomous tsim ntawm lub vuam trajectory.Lub hauv paus ntsiab lus ntawm laser ya davhlau vuam yog hais tias thaum lub laser beam tshwm sim ntawm X thiab Y tsom iav ntawm daim iav scanning, lub kaum sab xis ntawm daim iav yog tswj los ntawm autonomous programming kom ua tiav deflection ntawm lub laser beam ntawm txhua lub kaum ntse ntse.

Kev lig kev cai, laser vuam ntawm nws pib lub cev tsuas yog tso siab rau lub vuam neeg hlau los tsav lub laser vuam taub hau rau synchronous suab kom ua tiav cov nyhuv vuam.Txawm li cas los xij, qhov rov ua dua reciprocating tsab ntawv tsa suab ntawm cov vuam neeg hlau hnyav heev txwv kev ua haujlwm ntawm nws pib lub cev vuam vim muaj coob tus welds thiab qhov ntev ntawm cov welds.Hauv qhov sib piv, laser ya davhlau vuam tuaj yeem ua tiav nyob rau hauv ib qho chaw los ntawm kev kho lub kaum sab xis ntawm lub reflector.Yog li ntawd, laser ya dav hlau vuam tshuab tuaj yeem txhim kho qhov vuam efficiency thiab muaj kev cia siab rau daim ntawv thov dav.

Cov ntsiab lus

Nrog rau txoj kev loj hlob ntawm kev lag luam tsheb, lub neej yav tom ntej ntawm lub cev vuam tshuab yuav txuas ntxiv txhim kho nyob rau hauv ob qho tib si txheej txheem vuam thiab cov cuab yeej ntse.

Nws pib lub cev, tshwj xeeb tshaj yog lub zog tshiab lub tsheb lub cev, tab tom txhim kho nyob rau hauv cov kev taw qhia ntawm lub teeb yuag.Lub teeb yuag, cov ntaub ntawv sib xyaw thiab cov ntaub ntawv sib txawv yuav siv dav hauv nws lub cev, cov txheej txheem laser vuam yog qhov nyuaj kom ua tau raws li nws cov kev xav tau vuam, yog li cov txheej txheem vuam zoo thiab siv tau zoo yuav dhau los ua kev txhim kho yav tom ntej.

Nyob rau hauv xyoo tas los no, cov txheej txheem laser welding tshwm sim, xws li laser viav vias vuam, ntau lub laser beam welding, laser davhlau vuam, thiab lwm yam, tau nyob rau hauv vuam zoo thiab vuam efficiency ntawm thawj theoretical kev tshawb fawb thiab txheej txheem kev tshawb fawb.Lub neej yav tom ntej yuav tsum yog cov txheej txheem laser welding tshwm sim thiab nws pib lub cev hnyav cov ntaub ntawv, cov ntaub ntawv sib txawv ntawm vuam thiab lwm yam xwm txheej zoo sib xws, lub laser beam viav vias trajectory tsim, ntau lub laser beam zog ua haujlwm mechanism thiab davhlau vuam efficiency txhim kho thiab lwm yam hauv- kev tshawb fawb tob los tshawb txog lub teeb pom kev zoo pib lub cev vuam txheej txheem.

Nws pib lub cev laser vuam tshuab tau sib sib zog nqus ua ke nrog cov cuab yeej ntse, kev paub txog lub sijhawm ntawm nws lub cev laser vuam raws li txoj cai thiab kev tawm tswv yim tswj cov txheej txheem tsis muaj lub luag haujlwm txiav txim siab hauv vuam zoo.Lub tshuab ntse laser vuam tam sim no feem ntau yog siv rau kev npaj ua ntej vuam trajectory thiab taug qab thiab tom qab vuam zoo soj ntsuam.Kev tshawb fawb hauv tsev thiab txawv teb chaws hauv kev tshawb nrhiav cov vuam tsis xws luag thiab kev hloov kho cov kev cai ntawm cov tsis yog tseem nyob rau hauv nws cov me nyuam mos, thiab laser vuam txheej txheem tsis adaptive tswj tshuab tsis tau siv nyob rau hauv nws pib lub cev manufacturing.

Yog li ntawd, rau daim ntawv thov ntawm laser vuam tshuab nyob rau hauv nws pib lub cev vuam txheej txheem cov yam ntxwv, lub neej yav tom ntej yuav tsum tau tsim nrog advanced multi-sensor core laser vuam ntse sensing system thiab high-ceev high-precision vuam neeg hlau tswj system los xyuas kom meej tias lub laser vuam. Cov cuab yeej ntse hauv lub sijhawm tiag tiag thiab qhov tseeb ntawm txhua qhov txuas, los ntawm "kev npaj ua ntej-welding trajectory - welding tsis adaptive control post-welding quality online Inspection" link, kom ntseeg tau tias kev ua haujlwm zoo thiab ua haujlwm tau zoo.

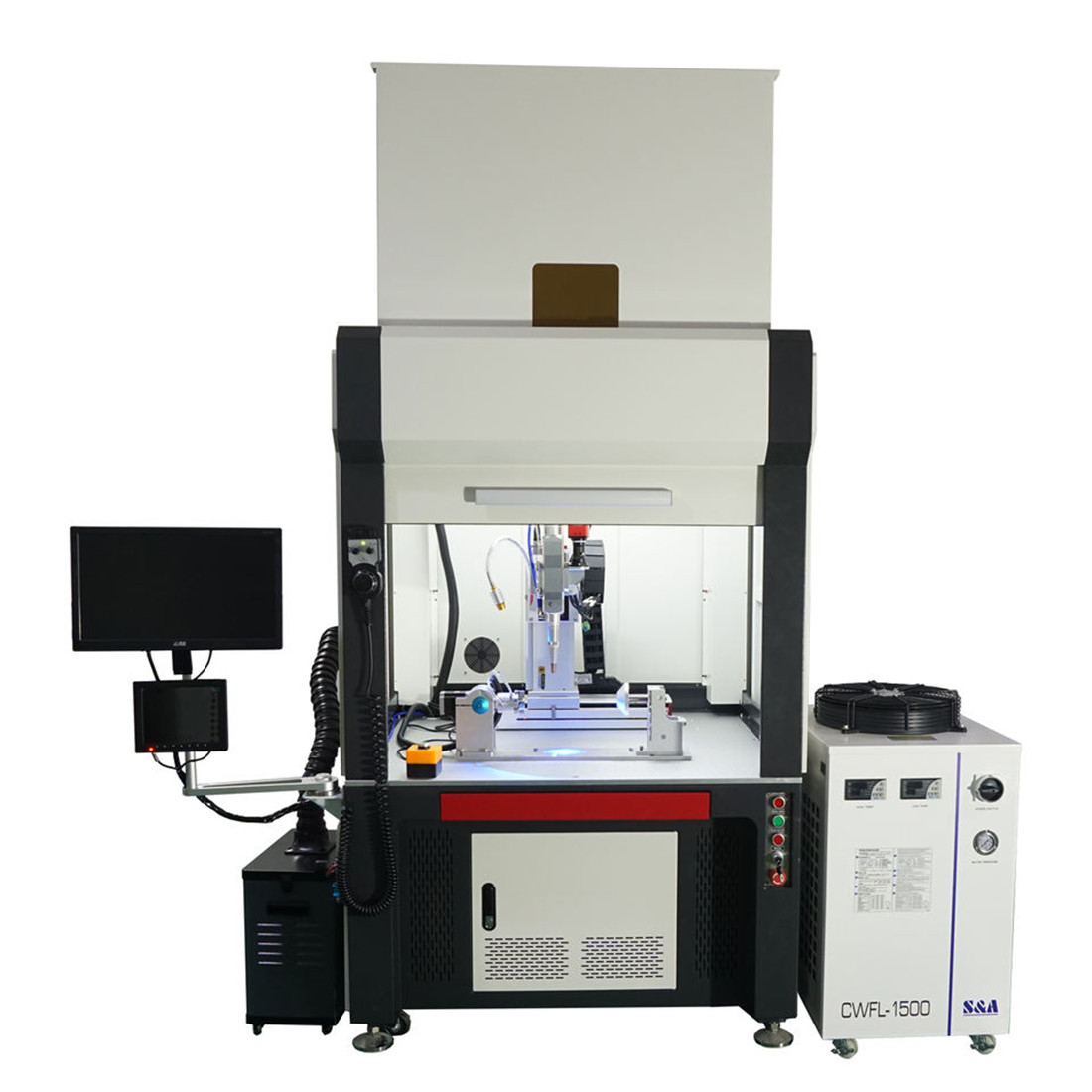

Maven laser automation tuam txhab tsom rau kev lag luam laser rau 14 xyoo, peb tshwj xeeb hauv laser vuam, peb muaj neeg hlau caj npab laser vuam tshuab, Rooj Tsis Siv Neeg Laser Vuam tshuab, Handheld Laser vuam tshuab, ntxiv rau, peb kuj muaj laser vuam tshuab, laser txiav tshuab. thiab laser npav engraving tshuab, peb muaj ntau ntawm laser welding daws teeb meem, yog tias koj xav tau koj tuaj yeem tiv tauj peb.

Post lub sij hawm: Dec-09-2022